Product Description

Company Profile

HangZhou Hilite Auto Parts Co., Ltd., Established In 2012, Professional Chinese Supplier Of Trailer Parts, Truck Parts And Agricultural Vehicle Parts. We Are a Professional & Modern Company Who Specializes In R&D, Production And Sales Of Leaf Spring ,Axles, Suspension,Brake System(Relay Valve,Abs…),Tank Trailer Accessories,Etc.

Our Advantages

Our Products Are Mainly Sold To Southeast Asia, Europe, Central And South America, The Middle East And Africa. Our Value Is To Gain More Market Share By Profit&Value Delivery Our Customers And Partners. CZPT Parts is Compatible with BP / Fw Accessories, Can Be Couple with SINOTRUCK/BENZ/FAW/XIHU (WEST LAKE) DIS.FENG… Trucks & Trailers. CZPT Is Committed To Providing Customer With Professional And Precise Services, High-Quality Products with Sufficient Experiecne.

OEM & Packing

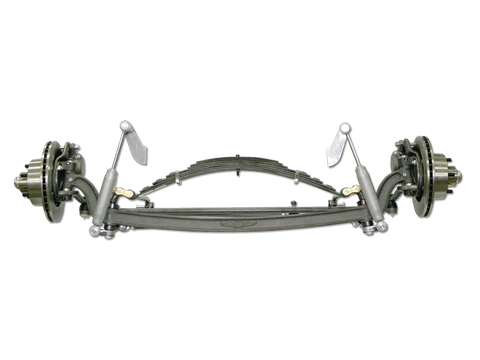

Product Description

| Axle Type | Max Capacity(t) | Track(mm) | Brake (mm) |

Spring Seat Installation | Axle Beam (mm) |

Centre Distance Of Brake Chamber(mm) | Wheel Fixing | Total Length (mm) |

Recommend Wheel | Axle Wright (kg) |

||

| Stud (ISO) | P.C.D(mm) | H(mm) | ||||||||||

| HLT-3AC5-8 | 8 | 1850 | 420*150 | ≥1080 | 127 | 428 | 10*M22*1.5 | 335 | 280.8 | ~2145 | 7.5V-20 | 323 |

| HLT-3AC5-10 | 13 | 1840 | 420*180 | ≥970 | 127 | 380 | 10*M22*1.5 | 335 | 280.8 | ~2180 | 7.5V-20 | 342 |

| HLT-3AC5-10 | 13 | 1840 | 420*180 | ≥930 | 150 | 380 | 10*M22*1.5 | 335 | 280.8 | ~2180 | 7.5V-20 | 340 |

| HLT-3AC5-11 | 14 | 1840 | 420*220 | ≥930 | 150 | 340 | 10*M22*1.5 | 335 | 280.8 | ~2180 | 7.5V-20 | 358 |

| HLT-3AC5-11 | 15 | 1850 | 420*180 | ≥940 | 150 | 390 | 10*M22*1.5 | 335 | 280.8 | ~2200 | 8.0V-20 | 370 |

| HLT-3AC5-11 | 16 | 1850 | 420*220 | ≥940 | 150 | 350 | 10*M22*1.5 | 335 | 280.8 | ~2200 | 8.0V-20 | 388 |

| HLT-3AC5-12 | 20 | 1850 | 420*220 | ≥940 | 150 | 345 | 10*M24*1.5 | 335 | 280.8 | ~2247 | 8.0V-20 | 430 |

| HLT-3AC5-12 | 25 | 1850 | 420*220 | ≥940 | 150 | 340 | 10*M24*1.5 | 335 | 280.8 | ~2215 | 8.0V-20 | 474 |

Hlt Specializes In R&D, Production And Sales Of Auto Leaf Springs, American &German Axles, Leaf Spring Suspensions, Air Suspensions, Hydraulic Suspensions, Rigid Suspensions And Other Types Of Suspensions, Single/Double Landing Gear, Electric Landing Gear, Hydraulic Landing Gear And Various Types Of Landing Gear , As Well As Tank Trailer Accessories Such As Manhole Covers, Discharge Valves, Subsea Valves, Etc. 500,000+ Types, One Stop Shopping For All.

Quality Comparasion

. Superior One-Piece Low-Alloy Axle Tube, Strong Carrying Capacity & High Bending Strength.

. Hardening And Tempering As a Whole, Cnc Machining.

. Brake Linings, Environment-Friendly Andnon-Asbestos, Wear Life Increased 25%.

. Xhp Mobil Grease To Lengthenmaintenance-Free Time.

. Bearing Is Designed For Heavy-Dutyvehicles, Famous Domestic Brand.

. Interchangeable Brake Components Ands-Camshaft Make Brake Action More Flexible.

Certifications

HLT Provide Guaranteed Services For All Products, Respect And Pay Attention To The Opinions Of Customers And Partners, Including Customizing And Developing New Products According To Customers’ Requirements, Believing Customer Satisfaction Is Our CZPT Pursuit. More Than 76% Of The Customers Who Have Used Hilite Products Have Become Our Loyal Customers, Who Have Established An Incredible Brand Effect For Us In The Local Area.

Factory View

We Would Like To Cooperate With You To Create More New Bonds In The Future.

FAQ

1Q: CAN YOU DESIGN AND PRODUCE THE PRODUCTS WE WANT?

A:We Have Rich Experience And Strong Technical Support To Design And Produce By Your Samples Or Drawings.Warmly Welcomed For Your Samples Or Drawing.

2Q:WHAT’S THE PROCESS OF PURCHASING ORDERS FROM YOU?

A:1.Send Us Your Specific Demand,Such As Oem Numbers, Photos, Trailer Models,Ect.

2.Confirm Our Quotation With Photos And Other Detials.

3.Negotiate About All Details You Need: Packing, Delivery Terms,Warranty, Ect.

4.Sign The Contract For The Payment,We Will Make The Production On Time.

3Q.WHAT IS YOUR TERMS OF PAYMENT?

A: T/T 30% As Deposit, And 70% Before Delivery.

L/C,T/T,D/P, Western Union,Paypal,Money Gram, Others

Photos And Videos Of The Products Will Be Provided Before Your Balance Payment.

4Q :WE WANT TO TRY IN A SMALL QUANTITY AS TRIAL ORDER,BUT LESS THAN YOUR MOQ. WHAT IS YOUR POLICY?

Sample Test And Sample Orders Could Be Accepted If We Have Ready Parts In Stock. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 12 Months |

|---|---|

| Condition: | New |

| Axle Number: | 1 |

| Application: | Trailer |

| Certification: | ISO, CCC BV SGS TUV |

| Material: | Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can beam axles be used in heavy-duty and commercial vehicles?

Beam axles are commonly used in heavy-duty and commercial vehicles due to their durability and load-bearing capabilities. These axles are well-suited for various applications in this category, and here’s why they are a popular choice:

1. Load-Carrying Capacity:

One of the key advantages of beam axles is their ability to handle heavy loads. This makes them ideal for heavy-duty and commercial vehicles designed to transport goods, equipment, or passengers. Beam axles can distribute the weight evenly, preventing overloading of specific wheels or axles.

2. Durability and Reliability:

Commercial vehicles often operate in demanding conditions, including rough roads, construction sites, and challenging terrains. Beam axles are known for their durability and resistance to damage. Their simple design and robust construction make them reliable in these environments, reducing downtime and maintenance costs.

3. Cost-Effectiveness:

For commercial vehicle manufacturers and operators, cost-effectiveness is a priority. Beam axles are cost-effective to produce, making them an attractive choice for vehicles where reducing production and maintenance costs is important.

4. Ease of Maintenance:

Maintenance is critical for commercial vehicles to ensure they remain operational. Beam axles are relatively easy to maintain, making it convenient for operators to keep their vehicles in working condition. Routine maintenance includes checking for wear, lubrication, and inspections, which can be performed without extensive specialized equipment.

5. Versatility:

Beam axles are versatile and can be adapted to different vehicle configurations. They can be used in single or multiple axles, including rear and front axles. This versatility allows manufacturers to design commercial vehicles for various applications, such as delivery trucks, buses, utility vehicles, and construction equipment.

6. Load Distribution:

Commercial vehicles often require even distribution of weight to comply with legal regulations and ensure safe operation. Beam axles help achieve this distribution by spreading the load across multiple axles, reducing the stress on individual components.

7. Off-Roading Capability:

In some commercial applications, vehicles need to operate off-road or on uneven terrain. Beam axles with their good ground clearance and robust design are well-suited for such applications, making them valuable for forestry trucks, mining vehicles, and agricultural equipment.

8. Customization:

Manufacturers can customize beam axles to accommodate specific load requirements, suspension configurations, and wheel sizes. This customization allows for tailoring the vehicles to meet the unique needs of various commercial industries.

Summary:

Beam axles are a practical choice for heavy-duty and commercial vehicles, offering load-carrying capacity, durability, and cost-effectiveness. Their ability to withstand challenging conditions, coupled with easy maintenance, makes them well-suited for a range of applications in the commercial and industrial sectors.

Are there specific driving conditions or terrains where beam axles perform better?

Beam axles are well-suited for certain driving conditions and terrains where their design and characteristics provide advantages. Here are some situations where beam axles may perform better:

1. Off-Road and Rough Terrain:

Beam axles are highly effective in off-road and rough terrain environments. Their key advantages in such conditions include:

- Ground Clearance: Beam axles often provide good ground clearance, allowing vehicles to navigate over rocks, ruts, and uneven terrain without getting stuck.

- Wheel Articulation: Beam axles offer excellent wheel articulation, allowing the wheels to maintain contact with the ground even when the terrain is uneven. This enhances traction and stability.

- Durability: Off-road environments can be punishing, and beam axles are known for their durability and resistance to damage from impacts and obstacles.

2. Heavy-Duty and Commercial Vehicles:

Beam axles are commonly used in heavy-duty and commercial vehicles due to their load-bearing capacity and robustness. In such applications:

- Weight Distribution: Beam axles help distribute the weight of the vehicle and cargo evenly, which is critical for load-bearing and stability in applications like trucks and buses.

- Durability and Longevity: Commercial vehicles endure extensive use, so the durability of beam axles is advantageous for minimizing maintenance and downtime.

3. Simplified Maintenance:

Beam axles are relatively easy to maintain and repair, making them suitable for applications where accessibility to service and maintenance is essential. Simple designs can save time and resources in maintenance operations.

4. Classic and Vintage Cars:

Some classic and vintage vehicles use beam axles, and enthusiasts appreciate the authenticity and historical significance of these designs. While they may not be the most advanced suspension systems, they offer a unique driving experience.

5. Towing and Trailering:

Beam axles are often used in trailers and semi-trailers, providing support for the trailer’s weight and cargo. Their load-bearing capacity and simplicity make them suitable for these applications.

6. Custom Off-Roading and 4×4 Vehicles:

Enthusiasts and off-road hobbyists often modify their vehicles with beam axles to improve off-road performance. Lifted suspensions and enhanced articulation can make custom 4×4 vehicles better suited for challenging terrains.

Summary:

Beam axles excel in specific driving conditions and terrains, particularly in off-road, heavy-duty, and commercial applications. Their robustness, ground clearance, and durability are key attributes that make them perform better in these environments. However, in everyday passenger cars and modern vehicles, independent suspension systems are more common due to their comfort and handling advantages on paved roads.

Are there different types of beam axles for various vehicle applications?

Yes, there are different types of beam axles designed for various vehicle applications. These variations in beam axles are tailored to meet the specific needs of different types of vehicles and usage scenarios. Here are some of the different types:

1. Front Beam Axles:

Front beam axles are typically used in commercial and heavy-duty trucks, as well as some off-road and industrial vehicles. They are designed to provide robust load-bearing capabilities and stability for front-wheel drive vehicles, especially those used in construction, mining, and transportation of heavy loads.

2. Rear Beam Axles:

Rear beam axles are commonly used in various vehicle types, including trucks, vans, and off-road vehicles. They offer load-carrying capacity and are suitable for applications where traction and durability are important. In trucks, the rear beam axle often supports the weight of the cargo.

3. Off-Road Beam Axles:

Off-road vehicles, such as 4×4 trucks and SUVs, use specialized beam axles designed for rugged terrain. These beam axles provide increased articulation and durability, allowing the vehicle to maintain traction and control in challenging off-road conditions.

4. Independent Beam Axles:

Some vehicles, particularly in the realm of all-terrain and recreational vehicles, feature independent beam axles. These axles combine the strength of beam axles with the ability to articulate independently, offering a compromise between load-bearing capacity and off-road performance.

5. Solid and Tube Beam Axles:

Beam axles can come in different designs, including solid and tube axles. Solid beam axles consist of a single, solid shaft, while tube axles are hollow, reducing weight while maintaining strength. The choice depends on the vehicle’s requirements.

6. Retro and Classic Beam Axles:

In the context of classic and retro vehicles, beam axles are sometimes retained for authenticity. Modern vehicles with retro styling may incorporate beam axles to capture the aesthetics and character of older vehicle designs.

7. Tandem Beam Axles:

In heavy-duty trucks and trailers, tandem beam axles are often used. These axles are arranged in tandem pairs to distribute the load more evenly and improve load-bearing capacity, making them suitable for long-haul transportation.

The choice of beam axle type depends on the intended use, vehicle design, and the specific demands of the application. Manufacturers select the appropriate beam axle configuration to optimize vehicle performance, load-carrying capacity, and durability for a given scenario.

editor by CX 2024-05-09