Product Description

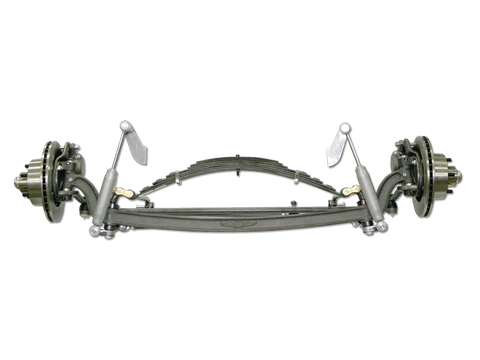

American type inboard axle for trailer

High quality & best price

CE: ISO9

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Axle Number: | 1 |

| Application: | Truck |

| Certification: | ISO |

| Material: | Steel |

| Type: | Semi-Trailer |

| Customization: |

Available

| Customized Request |

|---|

Can beam axles be used in heavy-duty and commercial vehicles?

Beam axles are commonly used in heavy-duty and commercial vehicles due to their durability and load-bearing capabilities. These axles are well-suited for various applications in this category, and here’s why they are a popular choice:

1. Load-Carrying Capacity:

One of the key advantages of beam axles is their ability to handle heavy loads. This makes them ideal for heavy-duty and commercial vehicles designed to transport goods, equipment, or passengers. Beam axles can distribute the weight evenly, preventing overloading of specific wheels or axles.

2. Durability and Reliability:

Commercial vehicles often operate in demanding conditions, including rough roads, construction sites, and challenging terrains. Beam axles are known for their durability and resistance to damage. Their simple design and robust construction make them reliable in these environments, reducing downtime and maintenance costs.

3. Cost-Effectiveness:

For commercial vehicle manufacturers and operators, cost-effectiveness is a priority. Beam axles are cost-effective to produce, making them an attractive choice for vehicles where reducing production and maintenance costs is important.

4. Ease of Maintenance:

Maintenance is critical for commercial vehicles to ensure they remain operational. Beam axles are relatively easy to maintain, making it convenient for operators to keep their vehicles in working condition. Routine maintenance includes checking for wear, lubrication, and inspections, which can be performed without extensive specialized equipment.

5. Versatility:

Beam axles are versatile and can be adapted to different vehicle configurations. They can be used in single or multiple axles, including rear and front axles. This versatility allows manufacturers to design commercial vehicles for various applications, such as delivery trucks, buses, utility vehicles, and construction equipment.

6. Load Distribution:

Commercial vehicles often require even distribution of weight to comply with legal regulations and ensure safe operation. Beam axles help achieve this distribution by spreading the load across multiple axles, reducing the stress on individual components.

7. Off-Roading Capability:

In some commercial applications, vehicles need to operate off-road or on uneven terrain. Beam axles with their good ground clearance and robust design are well-suited for such applications, making them valuable for forestry trucks, mining vehicles, and agricultural equipment.

8. Customization:

Manufacturers can customize beam axles to accommodate specific load requirements, suspension configurations, and wheel sizes. This customization allows for tailoring the vehicles to meet the unique needs of various commercial industries.

Summary:

Beam axles are a practical choice for heavy-duty and commercial vehicles, offering load-carrying capacity, durability, and cost-effectiveness. Their ability to withstand challenging conditions, coupled with easy maintenance, makes them well-suited for a range of applications in the commercial and industrial sectors.

Are there specific driving conditions or terrains where beam axles perform better?

Beam axles are well-suited for certain driving conditions and terrains where their design and characteristics provide advantages. Here are some situations where beam axles may perform better:

1. Off-Road and Rough Terrain:

Beam axles are highly effective in off-road and rough terrain environments. Their key advantages in such conditions include:

- Ground Clearance: Beam axles often provide good ground clearance, allowing vehicles to navigate over rocks, ruts, and uneven terrain without getting stuck.

- Wheel Articulation: Beam axles offer excellent wheel articulation, allowing the wheels to maintain contact with the ground even when the terrain is uneven. This enhances traction and stability.

- Durability: Off-road environments can be punishing, and beam axles are known for their durability and resistance to damage from impacts and obstacles.

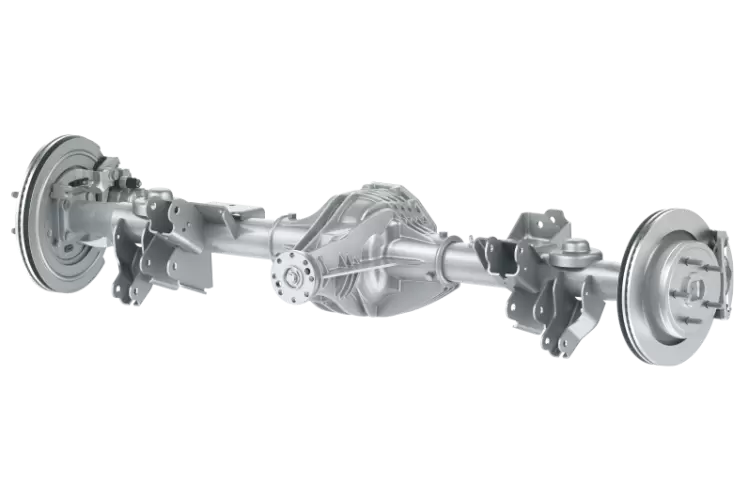

2. Heavy-Duty and Commercial Vehicles:

Beam axles are commonly used in heavy-duty and commercial vehicles due to their load-bearing capacity and robustness. In such applications:

- Weight Distribution: Beam axles help distribute the weight of the vehicle and cargo evenly, which is critical for load-bearing and stability in applications like trucks and buses.

- Durability and Longevity: Commercial vehicles endure extensive use, so the durability of beam axles is advantageous for minimizing maintenance and downtime.

3. Simplified Maintenance:

Beam axles are relatively easy to maintain and repair, making them suitable for applications where accessibility to service and maintenance is essential. Simple designs can save time and resources in maintenance operations.

4. Classic and Vintage Cars:

Some classic and vintage vehicles use beam axles, and enthusiasts appreciate the authenticity and historical significance of these designs. While they may not be the most advanced suspension systems, they offer a unique driving experience.

5. Towing and Trailering:

Beam axles are often used in trailers and semi-trailers, providing support for the trailer’s weight and cargo. Their load-bearing capacity and simplicity make them suitable for these applications.

6. Custom Off-Roading and 4×4 Vehicles:

Enthusiasts and off-road hobbyists often modify their vehicles with beam axles to improve off-road performance. Lifted suspensions and enhanced articulation can make custom 4×4 vehicles better suited for challenging terrains.

Summary:

Beam axles excel in specific driving conditions and terrains, particularly in off-road, heavy-duty, and commercial applications. Their robustness, ground clearance, and durability are key attributes that make them perform better in these environments. However, in everyday passenger cars and modern vehicles, independent suspension systems are more common due to their comfort and handling advantages on paved roads.

What is a beam axle, and how does it differ from independent suspension?

A beam axle, also known as a solid axle or live axle, is a type of suspension system used in vehicles. It differs from independent suspension in several ways:

Beam Axle:

- A beam axle consists of a single solid beam (shaft) that spans the width of the vehicle and connects both wheels on the same axle. It is a single rigid unit.

- Beam axles are commonly found in older vehicles and some heavy-duty trucks and off-road vehicles.

- When one wheel encounters a bump or obstacle, the other wheel on the same axle is affected. This can result in a less comfortable ride and reduced traction for both wheels.

- Beam axles are generally more robust and suitable for heavy loads, making them preferred in certain commercial and industrial applications.

- They are relatively simple in design and tend to be more cost-effective to manufacture and maintain.

Independent Suspension:

- Independent suspension, on the other hand, allows each wheel to move independently of the other. It consists of separate suspension units for each wheel.

- Independent suspension is commonly used in modern passenger cars, SUVs, and performance vehicles.

- Each wheel responds individually to road imperfections, providing a smoother and more comfortable ride. It also improves traction, handling, and stability.

- Independent suspension is generally lighter and offers better handling characteristics, making it suitable for most everyday driving situations.

- However, it can be more complex and costly to manufacture and maintain compared to beam axles.

While beam axles are known for their strength and simplicity, independent suspension systems are favored for their superior ride comfort, handling, and adaptability to various road conditions. The choice between the two depends on the vehicle’s intended use, design goals, and the trade-off between load-carrying capacity and ride quality.

editor by CX 2024-04-09