Product Description

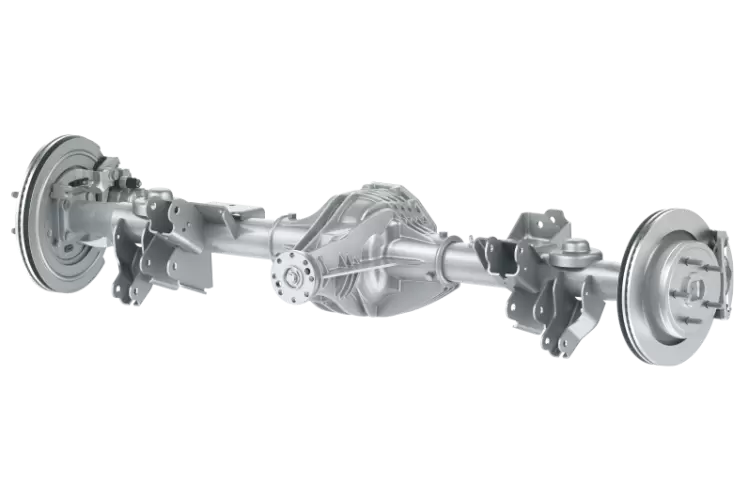

Trailer Parts 12ton Square Beam Trailer Axle/Semi Trailer Axle/Truck Axle

1.Company introduction:

ZheJiang CZPT Co.,Ltd is 1 of the major manufacturers specializing in the production of trailer axles.

Our company has high technological background, sophisticated manufacturing technology, advances detection means, perfect quality assurance system. It is a specialized manufacturer integrating scientific research, design, production and sales.

The production of “FUSAI” trailer axles passed the national authoritative department detection. The fatigue life is up to 1,500,000 times without damage-more than 3 times above the national standard, which is in the leading domestic level, and reach or exceed the international standards. Our products are popular not only in domestic markets, but all over the world. Since the products are designed and optimized by computer, they have reasonable structure, good braking performance, high strength and rigidity, strong bearing capacity, long service life, good service, trusted by the users.

2.”FUSAI” brand German type trailer axle is designed according to the related European standard. The rated loading capacity of this trailer parts is available from 12 ton to 18 ton.

1.German spindle design which is the widely used in the industry with proven performance

2.Low-alloy machined spindles, friction welded seamlessly, and overall heat treating process

3.Axle stubs and brake hubs are all CZPT forging, ensure they are more powerful and better steady

4.Special clone-shape design on the axle-shoulders, lessening stress concentration and enhancing anti-fatigue performance

5.Unique design on axle stubs (with a precise declination angel at both ends) to minimize tire wear

6.National and industry standard compliant set components

7.National Automobile Monitor and Inspection Center certified axle shaft that undergoes over 1.2 million times of Fatigue testing and built to meet or exceed national industry standards.

German type axle specifications:

|

Axle Type |

Max. Capacity (T) |

Track (mm) |

Brake (mm) |

Center Distance Of Spring Seat (mm) |

Axle Beam (mm) |

Center Distance Of Brake Chamber (mm) |

Stud

|

P.C.D (mm) |

Hole Diameter (mm) |

Total Length (mm) |

Recommended Wheel

|

Axle Weight (kg) |

|

FS- 12 |

12 |

1840 |

420* 200 |

≥980 |

150* 150 |

420 |

10* M22* 1.5 |

335 |

281 |

2158 |

7.5V-20 |

390 |

|

FS- 14 |

14 |

1840 |

420* 200 |

≥900 |

150* 150 |

430 |

10* M22* 1.5 |

335 |

281 |

2172 |

8.0V-20 |

417 |

|

FS- 16 |

16 |

1850 |

420* 200 |

≥900 |

150* 150 |

280 |

10* M22* 1.5 |

335 |

281 |

2245 |

8.5V-20 |

548 |

Attention:

1. Optional track length available.

2. Optional ABS and automatic slack adjuster available.

3. All the components are in common use of BPW.

4. Rights of changing product’s design and specification are reserved.

3.Scope of our business:

1.axles (German type axle, American type axle, Spoke axle, Axle without brake)

2.Suspension (Bogie suspension, Spoke suspension, Mechanical suspension)

3.Landing gear (Outboard or inboard)

4.Fifth wheel (2” 3.5”)

5.King pin (2” 3.5”)

6.Other axles and related parts (Low bed axle, hub, rims, spring, drum…)

Any question, contact Claire

ZheJiang CZPT Co., Ltd

| After-sales Service: | Available |

|---|---|

| Warranty: | 1 Year |

| Type: | Axle |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can beam axles be used in heavy-duty and commercial vehicles?

Beam axles are commonly used in heavy-duty and commercial vehicles due to their durability and load-bearing capabilities. These axles are well-suited for various applications in this category, and here’s why they are a popular choice:

1. Load-Carrying Capacity:

One of the key advantages of beam axles is their ability to handle heavy loads. This makes them ideal for heavy-duty and commercial vehicles designed to transport goods, equipment, or passengers. Beam axles can distribute the weight evenly, preventing overloading of specific wheels or axles.

2. Durability and Reliability:

Commercial vehicles often operate in demanding conditions, including rough roads, construction sites, and challenging terrains. Beam axles are known for their durability and resistance to damage. Their simple design and robust construction make them reliable in these environments, reducing downtime and maintenance costs.

3. Cost-Effectiveness:

For commercial vehicle manufacturers and operators, cost-effectiveness is a priority. Beam axles are cost-effective to produce, making them an attractive choice for vehicles where reducing production and maintenance costs is important.

4. Ease of Maintenance:

Maintenance is critical for commercial vehicles to ensure they remain operational. Beam axles are relatively easy to maintain, making it convenient for operators to keep their vehicles in working condition. Routine maintenance includes checking for wear, lubrication, and inspections, which can be performed without extensive specialized equipment.

5. Versatility:

Beam axles are versatile and can be adapted to different vehicle configurations. They can be used in single or multiple axles, including rear and front axles. This versatility allows manufacturers to design commercial vehicles for various applications, such as delivery trucks, buses, utility vehicles, and construction equipment.

6. Load Distribution:

Commercial vehicles often require even distribution of weight to comply with legal regulations and ensure safe operation. Beam axles help achieve this distribution by spreading the load across multiple axles, reducing the stress on individual components.

7. Off-Roading Capability:

In some commercial applications, vehicles need to operate off-road or on uneven terrain. Beam axles with their good ground clearance and robust design are well-suited for such applications, making them valuable for forestry trucks, mining vehicles, and agricultural equipment.

8. Customization:

Manufacturers can customize beam axles to accommodate specific load requirements, suspension configurations, and wheel sizes. This customization allows for tailoring the vehicles to meet the unique needs of various commercial industries.

Summary:

Beam axles are a practical choice for heavy-duty and commercial vehicles, offering load-carrying capacity, durability, and cost-effectiveness. Their ability to withstand challenging conditions, coupled with easy maintenance, makes them well-suited for a range of applications in the commercial and industrial sectors.

How does a live axle differ from a dead axle in the context of beam axles?

In the context of beam axles, live axles and dead axles represent two distinct configurations that serve different purposes and have specific characteristics:

Live Axle (Driven Axle):

A live axle is an axle that is actively connected to the engine and is responsible for driving the wheels. In a live axle configuration:

- The axle shafts are connected to the wheels and are capable of delivering power to propel the vehicle.

- The wheels on a live axle are actively powered and provide propulsion, typically in rear-wheel-drive or four-wheel-drive (4WD) vehicles.

- Live axles are common in trucks, off-road vehicles, and 4×4 vehicles, where the ability to provide power to multiple wheels is crucial for traction in challenging terrain.

- Live axles are sometimes referred to as “driven axles” because they actively drive the vehicle.

Dead Axle (Trailing or Support Axle):

A dead axle, in contrast, is an axle that is not powered and does not contribute to the vehicle’s propulsion. In a dead axle configuration:

- The axle shafts are not connected to the engine and do not receive power; they simply support the wheels.

- Dead axles are often used in the front of front-wheel-drive vehicles, where the engine provides power to the front wheels, and the rear wheels are supported by dead axles.

- These axles are also used in trailers and semi-trailers, where they support the weight of the trailer but do not provide power to the wheels.

- Dead axles are sometimes referred to as “trailing axles” or “support axles” because they do not actively drive the vehicle.

Differences:

The primary difference between live axles and dead axles in the context of beam axles is whether they are responsible for providing power to the wheels. Live axles actively drive the vehicle, while dead axles are passive and serve a support or trailing role. The choice between these configurations depends on the specific vehicle design and its intended use, with live axles favored for off-road and high-traction applications and dead axles used for support and weight distribution.

What are the advantages and disadvantages of using a beam axle?

A beam axle, also known as a solid axle or live axle, has its own set of advantages and disadvantages, which can make it suitable or less suitable for various vehicle applications:

Advantages of Using a Beam Axle:

- 1. Durability: Beam axles are known for their robust construction and ability to withstand heavy loads and rough terrain. They are commonly used in applications where durability and strength are paramount, such as in heavy-duty trucks and off-road vehicles.

- 2. Cost-Effective: Beam axles are generally simpler and more cost-effective to manufacture and maintain compared to independent suspension systems. This makes them an economical choice for certain vehicle types.

- 3. Load-Carrying Capacity: Vehicles with beam axles have excellent load-carrying capacity, making them suitable for applications that involve transporting heavy goods or towing trailers.

- 4. Articulation (Off-Road): In off-road and 4×4 vehicles, front and rear beam axles provide exceptional articulation, allowing the wheels to maintain contact with uneven terrain, enhancing off-road performance.

- 5. Simplicity: The design of a beam axle is straightforward and lacks complex components, making it easier to maintain and repair.

Disadvantages of Using a Beam Axle:

- 1. Ride Comfort: Vehicles with beam axles often provide a less comfortable ride, especially on uneven road surfaces, as both wheels on the same axle move together in response to bumps and imperfections.

- 2. Reduced Traction: In off-road or slippery conditions, the lack of independent wheel movement can reduce traction, as one wheel’s loss of grip affects the other on the same axle.

- 3. Handling and Stability: Beam axles may result in less precise handling and stability, particularly in high-speed or cornering situations, compared to vehicles with independent suspension.

- 4. Weight: The solid construction of a beam axle can add weight to the vehicle, which can impact fuel efficiency and overall performance.

- 5. Limited Applications: Beam axles are less versatile and are typically used in specific applications, such as rear axles in trucks, off-road vehicles, and some industrial vehicles. They are less common in modern passenger cars due to their limitations in ride comfort and handling.

The choice of whether to use a beam axle or independent suspension depends on the intended use of the vehicle and the trade-offs between durability, load-carrying capacity, ride comfort, and handling characteristics.

editor by CX 2023-11-13