Product Description

Product Description

| ` |

Product Parameters

|

Product Name |

Drive Shaft Center Support Bearings |

|

Material |

Chrome Steel, GCR15 |

|

Type |

single row,double row,four row |

|

Size |

d:3-150mm,D:9-225mm |

|

Grade |

PO,P6,P5,P4,P2 |

|

Cage |

Steel Cage,nylon Cage |

|

Used For |

Precision instruments, low-noise motors, automobiles, motorcycles and general machinery |

|

Warranty |

1 year |

|

Brand |

OEM |

|

Packing |

According to the buyer requests for packaging |

Specifition

|

Bearing No. |

Bearing No. |

Bearing No. |

Bearing No. |

|

HB206FF |

HB88508 |

HB88508E |

HB88512 |

|

HBD206FF |

HB88508A |

HB88509 |

HB88512A |

|

HB88107A |

HB88508AA |

HB88509A |

HB88512AS |

|

HB88107B |

HB88508AB |

HB88509B |

HB6207T |

|

HB88107C |

HB88508B |

HB88509C |

HB88507T |

|

HB88107D |

HB88508C |

HB88510 |

HB6207 |

|

HB88107E |

HB88508D |

HB88510S |

HB88507 |

|

HB6208 |

HB88508E |

HB6209 |

HB88509A |

|

HB6210L |

HB6210 |

HB88510H |

HB6011 |

|

HB6011H |

HB6212A |

HB6212 |

HB88512L |

|

HB88512A |

HB6014A |

|

|

FAQ

1. Your factory how to control the quality?

A: All bearing parts before the production and the production process, strict inspection by 100%, including crack detection, roundness, hardness, roughness, and the geometry size, all bearing meet ISO international standard.

2. Can you tell me the bearing material?

A: We have chrome steel GCR15, stainless steel, ceramics and other materials.

3. How long is your delivery time?

A: If the goods are in stock, usually 5 to 10 days, if the goods are no stock for 15 to 20 days, according to the quantity to determine the time.

4. OEM and custom you can receive?

A: Yes, accept OEM, can also be customized according to samples or drawings for you.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Semi Trailer Axle Wheel Hub Inner and Outer Taper |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

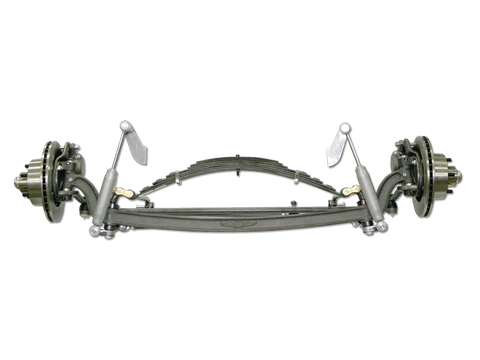

What are the considerations for off-road vehicles using beam axles?

Off-road vehicles that use beam axles have specific considerations to optimize performance and durability in challenging terrain. Here are the key factors to keep in mind when designing or using off-road vehicles with beam axles:

1. Ground Clearance:

Off-road vehicles require sufficient ground clearance to navigate over rocks, ruts, and uneven terrain. Beam axles, with their ability to provide good ground clearance, are a practical choice for these applications. Vehicle designers may also opt for suspension lifts to further increase ground clearance.

2. Wheel Articulation:

Off-roading often involves traversing uneven surfaces where individual wheel movement is essential to maintain traction and stability. Beam axles offer excellent wheel articulation, allowing each wheel to move independently and adapt to the terrain, keeping the tires in contact with the ground. This enhances the vehicle’s ability to overcome obstacles and maintain grip on challenging trails.

3. Durability and Impact Resistance:

Off-road environments can subject a vehicle to rough conditions and potential impacts from rocks, tree roots, and other obstacles. Beam axles are designed to be durable and resistant to damage. The choice of materials and construction should prioritize strength and impact resistance to ensure the axles can withstand the rigors of off-roading.

4. Suspension Tuning:

Off-road vehicles often require suspension tuning to achieve optimal performance. This includes selecting appropriate shock absorbers, springs, and other components to balance ride comfort and off-road capability. Tuning the suspension can improve handling, reduce body roll, and enhance overall off-road performance.

5. Differential Locking:

Off-road vehicles may benefit from differential locking mechanisms that ensure power is evenly distributed between the wheels on an axle. This helps prevent wheel spin and ensures that both wheels receive power for maximum traction. Locking differentials can be a valuable addition to vehicles with beam axles.

6. Tire Selection:

The choice of off-road tires is crucial. Tires with deep treads and appropriate tread patterns are essential for traction in mud, sand, and rocks. Tire pressure can also be adjusted to suit the terrain, and beadlock wheels can help secure the tires in challenging conditions.

7. Regular Maintenance:

Off-road vehicles with beam axles should undergo regular maintenance to ensure they remain in top condition. This includes inspecting and lubricating the axles, checking for signs of wear or damage, and addressing any issues promptly to prevent breakdowns during off-road adventures.

8. Customization:

Off-road enthusiasts often customize their vehicles with features like winches, skid plates, and roll cages to enhance off-road capabilities and safety. These modifications should be integrated with the beam axle suspension to ensure compatibility and functionality.

Summary:

Off-road vehicles using beam axles require careful consideration of ground clearance, wheel articulation, durability, and various other factors to optimize their performance in challenging terrains. Proper suspension tuning, tire selection, and maintenance are essential to ensure a safe and enjoyable off-roading experience.

Are there specific driving conditions or terrains where beam axles perform better?

Beam axles are well-suited for certain driving conditions and terrains where their design and characteristics provide advantages. Here are some situations where beam axles may perform better:

1. Off-Road and Rough Terrain:

Beam axles are highly effective in off-road and rough terrain environments. Their key advantages in such conditions include:

- Ground Clearance: Beam axles often provide good ground clearance, allowing vehicles to navigate over rocks, ruts, and uneven terrain without getting stuck.

- Wheel Articulation: Beam axles offer excellent wheel articulation, allowing the wheels to maintain contact with the ground even when the terrain is uneven. This enhances traction and stability.

- Durability: Off-road environments can be punishing, and beam axles are known for their durability and resistance to damage from impacts and obstacles.

2. Heavy-Duty and Commercial Vehicles:

Beam axles are commonly used in heavy-duty and commercial vehicles due to their load-bearing capacity and robustness. In such applications:

- Weight Distribution: Beam axles help distribute the weight of the vehicle and cargo evenly, which is critical for load-bearing and stability in applications like trucks and buses.

- Durability and Longevity: Commercial vehicles endure extensive use, so the durability of beam axles is advantageous for minimizing maintenance and downtime.

3. Simplified Maintenance:

Beam axles are relatively easy to maintain and repair, making them suitable for applications where accessibility to service and maintenance is essential. Simple designs can save time and resources in maintenance operations.

4. Classic and Vintage Cars:

Some classic and vintage vehicles use beam axles, and enthusiasts appreciate the authenticity and historical significance of these designs. While they may not be the most advanced suspension systems, they offer a unique driving experience.

5. Towing and Trailering:

Beam axles are often used in trailers and semi-trailers, providing support for the trailer’s weight and cargo. Their load-bearing capacity and simplicity make them suitable for these applications.

6. Custom Off-Roading and 4×4 Vehicles:

Enthusiasts and off-road hobbyists often modify their vehicles with beam axles to improve off-road performance. Lifted suspensions and enhanced articulation can make custom 4×4 vehicles better suited for challenging terrains.

Summary:

Beam axles excel in specific driving conditions and terrains, particularly in off-road, heavy-duty, and commercial applications. Their robustness, ground clearance, and durability are key attributes that make them perform better in these environments. However, in everyday passenger cars and modern vehicles, independent suspension systems are more common due to their comfort and handling advantages on paved roads.

Can you explain the role of a beam axle in a vehicle’s stability and handling?

A beam axle, also known as a solid axle or live axle, plays a significant role in a vehicle’s stability and handling, albeit with some trade-offs compared to independent suspension systems. Here’s an explanation of its role:

Stability:

- 1. Load Distribution: Beam axles contribute to even load distribution between the two wheels on the same axle. This helps maintain stability, especially when the vehicle is carrying heavy loads or towing trailers. It prevents one wheel from becoming excessively loaded, which can lead to uneven tire wear and instability.

- 2. Support for Heavy Loads: In applications that require carrying substantial weight, such as commercial trucks and heavy-duty vehicles, beam axles provide the necessary structural support. This ensures that the vehicle remains stable and can handle the load safely.

- 3. Rugged Terrain: In off-road and 4×4 vehicles, the solid construction of beam axles helps maintain stability and control on rough and uneven terrain. The axle’s ability to flex and maintain contact with the ground is crucial for off-road performance.

Handling:

- 1. Simplified Handling: Beam axles provide simplified handling characteristics. When both wheels on the same axle move together, it can result in predictable and straightforward handling, making them suitable for certain applications.

- 2. Improved Traction (Off-Road): In off-road vehicles, the ability of both wheels on a beam axle to move in unison enhances traction. When one wheel loses grip, the other compensates by maintaining contact with the terrain, increasing off-road capabilities.

- 3. Predictable Response: Vehicles with beam axles tend to provide a predictable response to steering inputs and road conditions, which can be an advantage in specific scenarios.

Limitations: While beam axles offer stability and simplified handling, they come with some limitations that can affect overall vehicle dynamics:

- 1. Reduced Comfort: On uneven road surfaces, the simultaneous movement of both wheels on a beam axle can result in a less comfortable ride due to the transmission of bumps and imperfections directly to the vehicle’s cabin.

- 2. Limited Handling Precision: Beam axles may result in less precise handling, especially in high-speed or cornering situations. The interconnected movement of wheels can lead to less agility and stability in such scenarios.

- 3. Reduced Adaptability: The handling characteristics of vehicles with beam axles are less adaptable to a wide range of road conditions compared to vehicles with independent suspension, which can adjust each wheel independently to changing terrain.

In summary, the role of a beam axle in a vehicle’s stability and handling is to provide even load distribution, support heavy loads, and maintain control in specific situations. However, this comes at the cost of reduced ride comfort and handling precision, making beam axles more suitable for certain applications, such as heavy-duty trucks, off-road vehicles, and scenarios where simplicity and load-carrying capacity are prioritized over comfort and precision.

editor by CX 2024-02-12