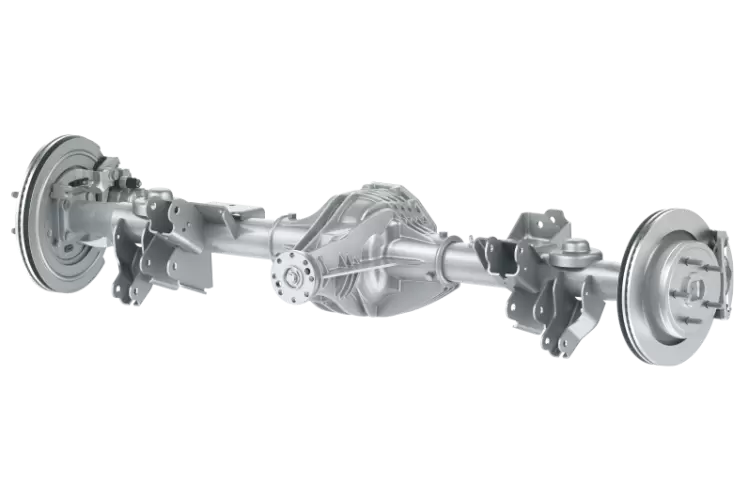

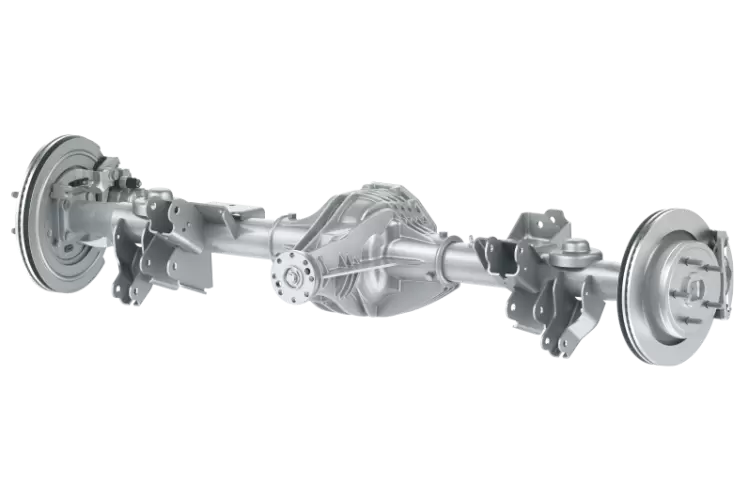

Product Description

American type inboard axle for trailer

High quality & best price

CE: ISO9

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Axle Number: | 1 |

| Application: | Truck |

| Certification: | ISO |

| Material: | Steel |

| Type: | Semi-Trailer |

| Customization: |

Available

| Customized Request |

|---|

How does a solid beam axle impact the ride quality of a vehicle?

A solid beam axle can have both positive and negative impacts on the ride quality of a vehicle. The specific effects depend on various factors, including the suspension setup, road conditions, and the vehicle’s intended use. Here’s how a solid beam axle influences ride quality:

1. Simplicity and Durability:

Positively, solid beam axles are known for their simplicity and durability. The absence of complex moving parts makes them robust and less prone to mechanical failures. This can contribute to a smoother ride over time, as there are fewer components to wear out or require maintenance.

2. Load Distribution:

A solid beam axle’s design allows for even distribution of weight across both wheels on the axle. This can lead to improved stability and handling, especially when carrying heavy loads. Vehicles with solid beam axles may have reduced body roll, enhancing the perception of ride quality.

3. Off-Road Capability:

Solid beam axles are commonly used in off-road vehicles due to their ability to maintain wheel contact with uneven terrain. In off-road applications, this feature can lead to a more comfortable ride, as the suspension flexes to absorb shocks and maintain traction on challenging surfaces.

4. Stiffness and Comfort:

On the downside, solid beam axles are generally stiffer compared to independent suspension systems. This stiffness can result in a less comfortable ride on smooth or well-paved roads. The vehicle may transmit more road imperfections and vibrations to the passengers.

5. Limited Articulation:

In certain situations, a solid beam axle’s limited articulation can impact ride quality. For example, when one wheel encounters a bump or obstacle, the other wheel is affected as well. This can lead to a bumpier ride compared to independent suspension systems, where each wheel can move independently to absorb shocks.

6. Road Conditions:

Ride quality is highly dependent on road conditions. On rough, uneven, or unpaved roads, a solid beam axle may perform better by maintaining wheel contact and stability. Conversely, on smooth and well-maintained roads, the ride quality may be less comfortable due to the stiffness of the axle.

7. Vehicle Design and Tuning:

Manufacturers can influence ride quality by designing the suspension components and tuning the shock absorbers to complement the solid beam axle. While the inherent stiffness remains, adjustments can be made to mitigate the negative effects and enhance comfort.

8. Passenger Expectations:

Ultimately, perceptions of ride quality can vary among passengers. Some may prioritize stability and load-carrying capacity, accepting the trade-off of a stiffer ride. Others may prioritize a smoother, more comfortable ride and opt for vehicles with independent suspension systems.

Summary:

The impact of a solid beam axle on ride quality is influenced by various factors, including the vehicle’s design, suspension tuning, and road conditions. While solid beam axles offer durability, load distribution, and off-road capability, they may result in a stiffer and less comfortable ride on smooth roads when compared to independent suspension systems.

How does a live axle differ from a dead axle in the context of beam axles?

In the context of beam axles, live axles and dead axles represent two distinct configurations that serve different purposes and have specific characteristics:

Live Axle (Driven Axle):

A live axle is an axle that is actively connected to the engine and is responsible for driving the wheels. In a live axle configuration:

- The axle shafts are connected to the wheels and are capable of delivering power to propel the vehicle.

- The wheels on a live axle are actively powered and provide propulsion, typically in rear-wheel-drive or four-wheel-drive (4WD) vehicles.

- Live axles are common in trucks, off-road vehicles, and 4×4 vehicles, where the ability to provide power to multiple wheels is crucial for traction in challenging terrain.

- Live axles are sometimes referred to as “driven axles” because they actively drive the vehicle.

Dead Axle (Trailing or Support Axle):

A dead axle, in contrast, is an axle that is not powered and does not contribute to the vehicle’s propulsion. In a dead axle configuration:

- The axle shafts are not connected to the engine and do not receive power; they simply support the wheels.

- Dead axles are often used in the front of front-wheel-drive vehicles, where the engine provides power to the front wheels, and the rear wheels are supported by dead axles.

- These axles are also used in trailers and semi-trailers, where they support the weight of the trailer but do not provide power to the wheels.

- Dead axles are sometimes referred to as “trailing axles” or “support axles” because they do not actively drive the vehicle.

Differences:

The primary difference between live axles and dead axles in the context of beam axles is whether they are responsible for providing power to the wheels. Live axles actively drive the vehicle, while dead axles are passive and serve a support or trailing role. The choice between these configurations depends on the specific vehicle design and its intended use, with live axles favored for off-road and high-traction applications and dead axles used for support and weight distribution.

Are there different types of beam axles for various vehicle applications?

Yes, there are different types of beam axles designed for various vehicle applications. These variations in beam axles are tailored to meet the specific needs of different types of vehicles and usage scenarios. Here are some of the different types:

1. Front Beam Axles:

Front beam axles are typically used in commercial and heavy-duty trucks, as well as some off-road and industrial vehicles. They are designed to provide robust load-bearing capabilities and stability for front-wheel drive vehicles, especially those used in construction, mining, and transportation of heavy loads.

2. Rear Beam Axles:

Rear beam axles are commonly used in various vehicle types, including trucks, vans, and off-road vehicles. They offer load-carrying capacity and are suitable for applications where traction and durability are important. In trucks, the rear beam axle often supports the weight of the cargo.

3. Off-Road Beam Axles:

Off-road vehicles, such as 4×4 trucks and SUVs, use specialized beam axles designed for rugged terrain. These beam axles provide increased articulation and durability, allowing the vehicle to maintain traction and control in challenging off-road conditions.

4. Independent Beam Axles:

Some vehicles, particularly in the realm of all-terrain and recreational vehicles, feature independent beam axles. These axles combine the strength of beam axles with the ability to articulate independently, offering a compromise between load-bearing capacity and off-road performance.

5. Solid and Tube Beam Axles:

Beam axles can come in different designs, including solid and tube axles. Solid beam axles consist of a single, solid shaft, while tube axles are hollow, reducing weight while maintaining strength. The choice depends on the vehicle’s requirements.

6. Retro and Classic Beam Axles:

In the context of classic and retro vehicles, beam axles are sometimes retained for authenticity. Modern vehicles with retro styling may incorporate beam axles to capture the aesthetics and character of older vehicle designs.

7. Tandem Beam Axles:

In heavy-duty trucks and trailers, tandem beam axles are often used. These axles are arranged in tandem pairs to distribute the load more evenly and improve load-bearing capacity, making them suitable for long-haul transportation.

The choice of beam axle type depends on the intended use, vehicle design, and the specific demands of the application. Manufacturers select the appropriate beam axle configuration to optimize vehicle performance, load-carrying capacity, and durability for a given scenario.

editor by CX 2024-04-23