Product Description

Product parameter

General information about TND axle CO., Ltd

HangZhou TND axle CO. Ltd, is a professional manufacturer for axle and auto parts, based in HangZhou, China, we pride ourselves on pushing the boundaries of engineering excellence, and our newest line of axles is no exception. Manufactured in our state-of-the-art facility in China, each axle is crafted with precision and expertise, incorporating the latest advancements in military-grade technology.

Here are just a few key features of our axles:

Unrivaled Durability: Built to withstand the most demanding conditions, our axles are engineered to last, ensuring minimal downtime for your fleet.

Precision Engineering: Every component is meticulously designed and manufactured to exacting standards, guaranteeing optimal performance and safety.

Enhanced Efficiency: Our axles are optimized for maximum efficiency, helping you streamline operations and reduce fuel consumption.

Advanced Technology: Utilizing cutting-edge technology, our axles offer state-of-the-art features to enhance control, stability, and overall performance.

By investing in our high-tech axles, you’re not just upgrading your fleet; you’re investing in reliability, efficiency, and peace of mind.

We sincerely welcome the opportunity to discuss how our axles can benefit your business specifically. Whether you’re looking to improve performance, reduce maintenance costs, or enhance the safety of your fleet, we have the solution you need.

Usage: Suitale for all-road condition across the globe

Quality Certificate: ISO certified

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 3 Years Warranty |

|---|---|

| Condition: | New |

| Axle Number: | 1 |

| Application: | Trailer |

| Certification: | ASTM, CE, ISO |

| Material: | Steel |

| Samples: |

US$ 350/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there potential challenges or limitations to using beam axles in vehicles?

Using beam axles in vehicles has both advantages and disadvantages. It’s important to consider the challenges and limitations associated with beam axles:

1. Ride Quality:

Beam axles are generally stiffer than independent suspension systems. This stiffness can lead to a less comfortable ride on smooth or well-paved roads, as they transmit more road imperfections and vibrations to the passengers. Passengers may perceive this as a limitation in terms of ride comfort.

2. Limited Articulation:

Beam axles have limited articulation. When one wheel encounters a bump or obstacle, the other wheel is affected as well. This can result in a bumpier ride compared to independent suspension systems, where each wheel can move independently to absorb shocks. Off-road vehicles may experience challenges in maintaining traction on rough terrains due to this limitation.

3. Reduced Traction in Some Scenarios:

Beam axles can experience reduced traction in certain scenarios, such as when one wheel loses contact with the ground. In off-road situations, this can limit the vehicle’s ability to traverse uneven terrain, especially when compared to independent suspension systems that allow each wheel to react independently to ground conditions.

4. Challenging Maneuverability:

Maneuverability can be a limitation in vehicles with beam axles. The stiffness and design of beam axles can make it harder to navigate tight spaces or execute sharp turns. This can be a drawback, especially in urban environments or when parking in confined areas.

5. Weight Distribution:

Proper weight distribution is crucial for vehicle stability. Beam axles, while offering even weight distribution between wheels on the same axle, may not provide the same level of precision in weight distribution as independent suspension systems. This can affect handling and stability in some situations.

6. Limited Ride Comfort on Smooth Roads:

On smooth and well-paved roads, solid beam axles may lead to reduced ride comfort due to their stiffness. Passengers may experience a more jarring ride, and the vehicle may struggle to absorb minor road imperfections.

7. Noise and Vibration:

Beam axles can transmit more noise and vibration from the road to the vehicle’s occupants. This can result in a less refined and quieter cabin environment compared to vehicles with independent suspension systems.

8. Suspension Tuning Challenges:

Designing the suspension components and tuning the shock absorbers for vehicles with beam axles can be challenging. Manufacturers must strike a balance between load-carrying capacity and ride comfort. Achieving an ideal balance can be difficult and may require compromises.

9. Vehicle-Specific Considerations:

The limitations of beam axles can vary depending on the vehicle’s intended use and design. While some limitations may be acceptable in off-road or heavy-duty applications, they may not be suitable for passenger cars or vehicles designed for urban commuting.

Summary:

Beam axles offer advantages in terms of durability and load distribution, but they also come with limitations related to ride comfort, maneuverability, and traction in certain scenarios. Vehicle manufacturers must carefully consider these limitations and weigh them against the specific needs and intended use of the vehicle.

Can you explain the impact of beam axles on a vehicle’s ground clearance?

The choice of suspension, including beam axles, can have a significant impact on a vehicle’s ground clearance, which is the distance between the lowest point of the vehicle and the ground. Here’s how beam axles can affect ground clearance:

1. Beam Axles and Ground Clearance:

Beam axles are known for their simplicity and durability, making them a common choice in certain vehicle types. Here’s how they influence ground clearance:

- Raised Chassis: Vehicles equipped with beam axles tend to have a raised chassis because the axle itself, along with its components, is located below the vehicle’s frame. This design provides a good amount of ground clearance, especially in off-road and heavy-duty vehicles.

- Consistent Clearance: Beam axles maintain a relatively consistent ground clearance across the width of the vehicle. This even clearance can be advantageous when traversing uneven terrain, as all wheels have similar clearance levels.

2. Impact on Off-Roading:

Beam axles are favored in off-road vehicles and 4x4s because they offer several advantages for tackling rough terrain:

- Improved Articulation: Beam axles provide excellent wheel articulation, allowing the wheels to move independently, which can keep the tires in contact with the ground even on uneven surfaces.

- Enhanced Durability: Off-road vehicles need to withstand impacts, rocks, and obstacles. Beam axles are less prone to damage in these conditions, contributing to a higher ground clearance.

- Adaptability: Off-road enthusiasts often modify their vehicles with suspension lifts to further increase ground clearance when using beam axles, enabling them to conquer more challenging trails.

3. Passenger Cars and Beam Axles:

Beam axles are less common in passenger cars, where independent suspension systems are preferred for better ride comfort and handling on paved roads. However, some classic and vintage cars may feature beam axles in the rear suspension, affecting their ground clearance and ride characteristics.

4. Balancing Act:

When designing vehicles with beam axles, engineers aim to strike a balance between ground clearance, stability, and load-bearing capacity. The height of the axle, suspension components, and tire size all contribute to the final ground clearance measurement.

Summary:

Beam axles can provide vehicles with good ground clearance, especially in off-road and heavy-duty applications. Their ability to maintain even clearance and handle uneven terrain makes them a practical choice for specific vehicle types. However, the impact of beam axles on ground clearance varies depending on the vehicle’s design, intended use, and modifications made by enthusiasts.

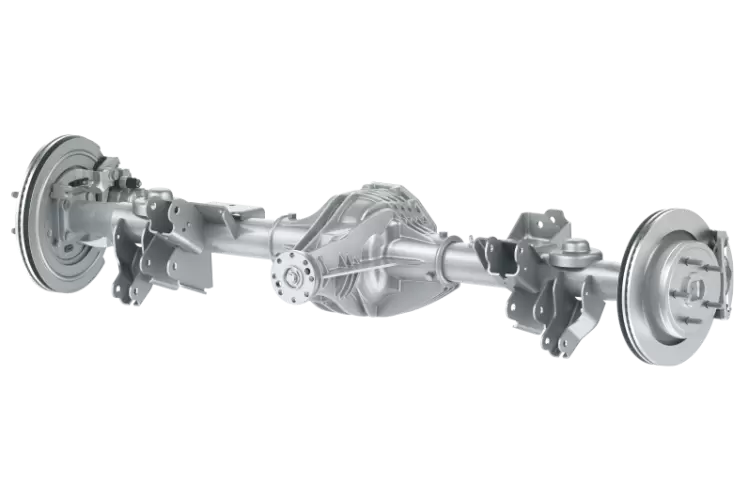

How does a solid beam axle work in the suspension of a vehicle?

A solid beam axle, also known as a live axle, is a type of suspension system commonly used in various vehicles. It operates differently from independent suspension systems, and its function can vary depending on whether it’s used as a rear axle or front axle in a vehicle:

Rear Solid Beam Axle:

In vehicles with rear solid beam axles, the following key characteristics define how they work in the suspension:

- Single Solid Axle: A solid beam axle is a single, rigid axle that spans the width of the vehicle. It connects both rear wheels and is a single, solid unit.

- Equal Wheel Movement: When one wheel on the axle encounters a bump or road imperfection, the other wheel on the same axle is affected. Both wheels move up and down together, and this movement is linked by the axle.

- Simple and Robust: Solid beam axles are known for their simplicity and robustness. They can handle heavy loads and provide durability, making them suitable for applications like trucks, SUVs, and some off-road vehicles.

Front Solid Beam Axle:

Front solid beam axles are less common in modern vehicles but are used in some specific applications. Their operation is as follows:

- Single Solid Axle: Like the rear version, the front solid beam axle is a single, solid axle spanning the width of the vehicle.

- Equal Wheel Movement: The front solid beam axle connects both front wheels. When one wheel encounters an obstacle, both front wheels move up and down together, as they are linked by the axle.

- Off-Road Performance: Front solid beam axles are often used in off-road and 4×4 vehicles because they provide excellent articulation and durability, making them suitable for rugged terrain.

The key aspect of solid beam axles is that they do not allow independent movement of the wheels on the same axle. This means that when one wheel encounters an obstacle, the other wheel is affected as well. While this setup can provide robustness and load-carrying capacity, it may result in a less comfortable ride and reduced traction on uneven surfaces compared to vehicles with independent suspension.

It’s important to note that the choice between solid beam axles and independent suspension depends on the vehicle’s intended use, design goals, and the trade-off between load-carrying capacity and ride quality.

editor by CX 2024-05-09

China high quality Gjf Brand One Stop Service Outer and Inner CV Joint Rear Front Drive Shaft CV Axle for CZPT Np300 D23 2017 C-Ni111-8h cv axle replacement

Product Description

Product Description

Our Advantages:

1.We are manufacturer of drive shaft,cv joint and cv boot, we have more than 20-years experience in producing and selling auto parts.

2.We have strict quality control, the quality of our products is very good.

3.We are professional in different market around the world.

4.The reviews our customers given us are very positive, we have confidence in our products.

5.OEM/ODM is available, meet your requirements well.

6.Large warehouse, huge stocks!!! friendly for those customers who want some quantity.

7.Ship products out very fastly, we have stock.

→→More detail pictures of our products,

Pls contact us!!

| Product Name | One stop purchase of drive shaft and cv joint | Material | 42CrMo alloy steel |

| Car fitment | Nissan | Warranty | 12 months |

| Model | for NISSAN NP300 D23 2017 C-NI111-8H | Place of origin | ZHangZhoug, China |

| Productive year | pls contact us for more details | MOQ | 4 PCS |

| OE number | factory standard | Delivery time | 1-7 days |

| OEM/ODM | Yes | Brand | GJF |

| Packing size | according to each model | Payment | L/C,T/T,western Union,Cash,PayPal |

| Sample service | Depends on the situation of stock | Weight | 7.9KG |

Detailed Photos

Customer Review

Packaging & Shipping

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 12 Months Warranty |

|---|---|

| Condition: | New |

| Color: | Black |

| Certification: | CE, DIN, ISO |

| Type: | Universal Joint |

| Application Brand: | Nissan |

| Samples: |

US$ 1.15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide insights into the maintenance of axle bearings for smooth operation?

Maintaining axle bearings is essential for ensuring smooth operation, longevity, and optimal performance of a vehicle’s axle system. Here are some insights into the maintenance of axle bearings:

1. Regular Inspection:

Perform regular visual inspections of the axle bearings to check for any signs of wear, damage, or leaks. Look for indications such as excessive play, unusual noises, vibration, or leakage of grease. Inspections should be carried out as per the manufacturer’s recommended intervals or during routine maintenance checks.

2. Lubrication:

Adequate lubrication is crucial for the smooth operation of axle bearings. Follow the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for greasing. Over-greasing or under-greasing can lead to bearing damage or failure. Ensure that the proper amount of grease is applied to the bearings, and use a high-quality grease that is compatible with the axle bearing specifications.

3. Seal Inspection and Replacement:

Check the condition of the axle bearing seals regularly. The seals help to keep contaminants out and retain the lubricating grease within the bearing. If the seals are damaged, worn, or show signs of leakage, they should be replaced promptly to prevent dirt, water, or debris from entering the bearing assembly and causing damage.

4. Proper Installation:

During axle bearing replacement or installation, it is crucial to follow proper procedures to ensure correct seating and alignment. Improper installation can lead to premature bearing failure and other issues. Refer to the manufacturer’s instructions or consult a professional mechanic to ensure proper installation techniques are followed.

5. Load Capacity and Alignment:

Ensure that the axle bearings are properly sized and rated to handle the load capacity of the vehicle and the specific application. Overloading the bearings can lead to excessive wear and premature failure. Additionally, proper wheel alignment is important to prevent uneven bearing wear. Regularly check and adjust the wheel alignment if necessary.

6. Environmental Considerations:

Take into account the operating conditions and environment in which the vehicle is used. Extreme temperatures, exposure to water, dirt, or corrosive substances can affect the performance of axle bearings. In such cases, additional preventive measures may be necessary, such as more frequent inspections, cleaning, and lubrication.

7. Professional Maintenance:

If you are unsure about performing maintenance on axle bearings yourself or if you encounter complex issues, it is recommended to seek assistance from a qualified mechanic or technician who has experience with axle systems. They can provide expert advice, perform necessary repairs or replacements, and ensure proper maintenance of the axle bearings.

By following these maintenance insights, you can help ensure the smooth operation, longevity, and reliability of axle bearings, contributing to the overall performance and safety of the vehicle.

Can you provide insights into the advancements in axle technology in recent years?

In recent years, there have been significant advancements in axle technology to enhance performance, efficiency, and safety in vehicles. Here are some insights into the key advancements:

- Lightweight Materials:

- Electronic Differential:

- Advanced Axle Bearings:

- Electric Axles:

- Active Suspension Integration:

- Improved Sealing and Lubrication:

- Autonomous Vehicle Integration:

One notable advancement is the use of lightweight materials in axle construction. Manufacturers have increasingly utilized materials such as aluminum alloys and high-strength steels to reduce the weight of axles without compromising strength and durability. Lighter axles contribute to improved fuel efficiency and overall vehicle performance.

Electronic differentials, also known as eDiffs, have gained popularity in recent years. They utilize sensors, actuators, and control algorithms to monitor and distribute torque between the wheels more efficiently. Electronic differentials enhance traction, stability, and handling by actively managing torque distribution, especially in vehicles equipped with advanced stability control systems.

Axle bearings have seen advancements in design and materials to reduce friction, improve efficiency, and enhance durability. For example, the use of roller bearings or tapered roller bearings has become more prevalent, offering reduced frictional losses and improved load-carrying capacity. Some manufacturers have also introduced sealed or maintenance-free bearings to minimize maintenance requirements.

With the rise of electric vehicles (EVs) and hybrid vehicles, electric axles have emerged as a significant technological advancement. Electric axles integrate electric motors, power electronics, and gear systems into the axle assembly. They eliminate the need for traditional drivetrain components, simplify vehicle packaging, and offer benefits such as instant torque, regenerative braking, and improved energy efficiency.

Advancements in axle technology have facilitated the integration of active suspension systems into axle designs. Active suspension systems use sensors, actuators, and control algorithms to adjust the suspension characteristics in real-time, providing improved ride comfort, handling, and stability. Axles with integrated active suspension components offer more precise control over vehicle dynamics.

Axles have seen advancements in sealing and lubrication technologies to enhance durability and minimize maintenance requirements. Improved sealing systems help prevent contamination and retain lubricants, reducing the risk of premature wear or damage. Enhanced lubrication systems with better heat dissipation and reduced frictional losses contribute to improved efficiency and longevity.

The development of autonomous vehicles has spurred advancements in axle technology. Axles are being designed to accommodate the integration of sensors, actuators, and communication systems necessary for autonomous driving. These advancements enable seamless integration with advanced driver-assistance systems (ADAS) and autonomous driving features, ensuring optimal performance and safety.

It’s important to note that the specific advancements in axle technology can vary across different vehicle manufacturers and models. Furthermore, ongoing research and development efforts continue to drive further innovations in axle design, materials, and functionalities.

For the most up-to-date and detailed information on axle technology advancements, it is advisable to consult automotive manufacturers, industry publications, and reputable sources specializing in automotive technology.

What are the factors to consider when choosing an axle for a custom-built vehicle?

Choosing the right axle for a custom-built vehicle is crucial for ensuring optimal performance, durability, and safety. Here are several key factors to consider when selecting an axle for a custom-built vehicle:

- Vehicle Type and Intended Use:

- Axle Type:

- Weight Capacity:

- Axle Ratio:

- Braking System Compatibility:

- Suspension Compatibility:

- Aftermarket Support:

- Budget:

Consider the type of vehicle you are building and its intended use. Factors such as vehicle weight, power output, terrain (on-road or off-road), towing capacity, and payload requirements will influence the axle selection. Off-road vehicles may require axles with higher strength and durability, while performance-oriented vehicles may benefit from axles that can handle increased power and torque.

Choose the appropriate axle type based on your vehicle’s drivetrain configuration. Common axle types include solid axles (live axles) and independent axles. Solid axles are often used in heavy-duty applications and off-road vehicles due to their robustness and ability to handle high loads. Independent axles offer improved ride quality and handling characteristics but may have lower load-carrying capacities.

Determine the required weight capacity of the axle based on the vehicle’s weight and intended payload. It’s crucial to select an axle that can handle the anticipated loads without exceeding its weight rating. Consider factors such as cargo, passengers, and accessories that may contribute to the overall weight.

Choose an axle ratio that matches your vehicle’s powertrain and desired performance characteristics. The axle ratio affects the torque multiplication between the engine and wheels, influencing acceleration, towing capability, and fuel efficiency. Higher axle ratios provide more torque multiplication for improved low-end power but may sacrifice top-end speed.

Ensure that the chosen axle is compatible with your vehicle’s braking system. Consider factors such as the axle’s mounting provisions for brake calipers, rotor size compatibility, and the need for an anti-lock braking system (ABS) if required.

Consider the compatibility of the chosen axle with your vehicle’s suspension system. Factors such as axle mounting points, suspension geometry, and overall ride height should be taken into account. Ensure that the axle can be properly integrated with your chosen suspension components and that it provides sufficient ground clearance for your specific application.

Consider the availability of aftermarket support for the chosen axle. This includes access to replacement parts, upgrade options, and technical expertise. A robust aftermarket support network can be beneficial for future maintenance, repairs, and customization needs.

Set a realistic budget for the axle selection, keeping in mind that high-performance or specialized axles may come at a higher cost. Balance your requirements with your budget to find the best axle option that meets your needs without exceeding your financial limitations.

When choosing an axle for a custom-built vehicle, it’s recommended to consult with knowledgeable professionals, experienced builders, or reputable axle manufacturers. They can provide valuable guidance, assist in understanding technical specifications, and help you select the most suitable axle for your specific custom vehicle project.

editor by CX 2024-03-02

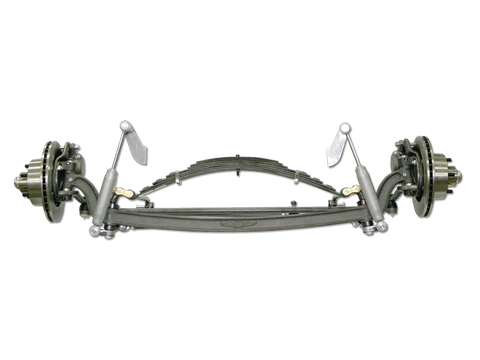

China Standard Axle Shaft and Beam Front Axle for Truck Trailer Parts cv axle replacement

Product Description

Product Description

Semi Trailer 1840 Square beam German axle for sale

| Type | MAX Capacity | A/B(mm) | C(mm) | E*F*T(mm) | L3(mm) | L2(mm) | L1(mm) | I(mm) | Weight(Kg) |

| ZBJZ-011 | 13T | 88.9/88.9 | UNS3.48-12 | 150*150*12 | 390 | 1296 | 1644 | 2108 | 120 |

| ZBJZ-012 | 13T | 95/85 | M85*2.5 | 150*150*12 | 354 | 1300 | 1645 | 2104 | 120 |

| ZBJZ-013 | 14T | 88.9/88.9 | UNS3.48-12 | 150*150*12 | 350 | 1258 | 1644 | 2108 | 120 |

| ZBJZ-014 | 16T | 99.9/88.9 | UNS3.48-12 | 150*150*14 | 360 | 1266 | 1664 | 2128 | 140 |

| ZBJZ-015 | 20T | 110/88.9 | UNS3.48-12 | 150*150*16 | 360 | 1264 | 1700 | 2173 | 160 |

Our factory

Loading

Fair&Certifictae

| Type: | Semi-Trailer |

|---|---|

| Load Capacity: | 28ton |

| Certification: | ECE, GCC, CE, ISO9001, DOT, CCC, ISO/TS16949 |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the considerations for off-road vehicles using beam axles?

Off-road vehicles that use beam axles have specific considerations to optimize performance and durability in challenging terrain. Here are the key factors to keep in mind when designing or using off-road vehicles with beam axles:

1. Ground Clearance:

Off-road vehicles require sufficient ground clearance to navigate over rocks, ruts, and uneven terrain. Beam axles, with their ability to provide good ground clearance, are a practical choice for these applications. Vehicle designers may also opt for suspension lifts to further increase ground clearance.

2. Wheel Articulation:

Off-roading often involves traversing uneven surfaces where individual wheel movement is essential to maintain traction and stability. Beam axles offer excellent wheel articulation, allowing each wheel to move independently and adapt to the terrain, keeping the tires in contact with the ground. This enhances the vehicle’s ability to overcome obstacles and maintain grip on challenging trails.

3. Durability and Impact Resistance:

Off-road environments can subject a vehicle to rough conditions and potential impacts from rocks, tree roots, and other obstacles. Beam axles are designed to be durable and resistant to damage. The choice of materials and construction should prioritize strength and impact resistance to ensure the axles can withstand the rigors of off-roading.

4. Suspension Tuning:

Off-road vehicles often require suspension tuning to achieve optimal performance. This includes selecting appropriate shock absorbers, springs, and other components to balance ride comfort and off-road capability. Tuning the suspension can improve handling, reduce body roll, and enhance overall off-road performance.

5. Differential Locking:

Off-road vehicles may benefit from differential locking mechanisms that ensure power is evenly distributed between the wheels on an axle. This helps prevent wheel spin and ensures that both wheels receive power for maximum traction. Locking differentials can be a valuable addition to vehicles with beam axles.

6. Tire Selection:

The choice of off-road tires is crucial. Tires with deep treads and appropriate tread patterns are essential for traction in mud, sand, and rocks. Tire pressure can also be adjusted to suit the terrain, and beadlock wheels can help secure the tires in challenging conditions.

7. Regular Maintenance:

Off-road vehicles with beam axles should undergo regular maintenance to ensure they remain in top condition. This includes inspecting and lubricating the axles, checking for signs of wear or damage, and addressing any issues promptly to prevent breakdowns during off-road adventures.

8. Customization:

Off-road enthusiasts often customize their vehicles with features like winches, skid plates, and roll cages to enhance off-road capabilities and safety. These modifications should be integrated with the beam axle suspension to ensure compatibility and functionality.

Summary:

Off-road vehicles using beam axles require careful consideration of ground clearance, wheel articulation, durability, and various other factors to optimize their performance in challenging terrains. Proper suspension tuning, tire selection, and maintenance are essential to ensure a safe and enjoyable off-roading experience.

Can you explain the impact of beam axles on a vehicle’s ground clearance?

The choice of suspension, including beam axles, can have a significant impact on a vehicle’s ground clearance, which is the distance between the lowest point of the vehicle and the ground. Here’s how beam axles can affect ground clearance:

1. Beam Axles and Ground Clearance:

Beam axles are known for their simplicity and durability, making them a common choice in certain vehicle types. Here’s how they influence ground clearance:

- Raised Chassis: Vehicles equipped with beam axles tend to have a raised chassis because the axle itself, along with its components, is located below the vehicle’s frame. This design provides a good amount of ground clearance, especially in off-road and heavy-duty vehicles.

- Consistent Clearance: Beam axles maintain a relatively consistent ground clearance across the width of the vehicle. This even clearance can be advantageous when traversing uneven terrain, as all wheels have similar clearance levels.

2. Impact on Off-Roading:

Beam axles are favored in off-road vehicles and 4x4s because they offer several advantages for tackling rough terrain:

- Improved Articulation: Beam axles provide excellent wheel articulation, allowing the wheels to move independently, which can keep the tires in contact with the ground even on uneven surfaces.

- Enhanced Durability: Off-road vehicles need to withstand impacts, rocks, and obstacles. Beam axles are less prone to damage in these conditions, contributing to a higher ground clearance.

- Adaptability: Off-road enthusiasts often modify their vehicles with suspension lifts to further increase ground clearance when using beam axles, enabling them to conquer more challenging trails.

3. Passenger Cars and Beam Axles:

Beam axles are less common in passenger cars, where independent suspension systems are preferred for better ride comfort and handling on paved roads. However, some classic and vintage cars may feature beam axles in the rear suspension, affecting their ground clearance and ride characteristics.

4. Balancing Act:

When designing vehicles with beam axles, engineers aim to strike a balance between ground clearance, stability, and load-bearing capacity. The height of the axle, suspension components, and tire size all contribute to the final ground clearance measurement.

Summary:

Beam axles can provide vehicles with good ground clearance, especially in off-road and heavy-duty applications. Their ability to maintain even clearance and handle uneven terrain makes them a practical choice for specific vehicle types. However, the impact of beam axles on ground clearance varies depending on the vehicle’s design, intended use, and modifications made by enthusiasts.

What is a beam axle, and how does it differ from independent suspension?

A beam axle, also known as a solid axle or live axle, is a type of suspension system used in vehicles. It differs from independent suspension in several ways:

Beam Axle:

- A beam axle consists of a single solid beam (shaft) that spans the width of the vehicle and connects both wheels on the same axle. It is a single rigid unit.

- Beam axles are commonly found in older vehicles and some heavy-duty trucks and off-road vehicles.

- When one wheel encounters a bump or obstacle, the other wheel on the same axle is affected. This can result in a less comfortable ride and reduced traction for both wheels.

- Beam axles are generally more robust and suitable for heavy loads, making them preferred in certain commercial and industrial applications.

- They are relatively simple in design and tend to be more cost-effective to manufacture and maintain.

Independent Suspension:

- Independent suspension, on the other hand, allows each wheel to move independently of the other. It consists of separate suspension units for each wheel.

- Independent suspension is commonly used in modern passenger cars, SUVs, and performance vehicles.

- Each wheel responds individually to road imperfections, providing a smoother and more comfortable ride. It also improves traction, handling, and stability.

- Independent suspension is generally lighter and offers better handling characteristics, making it suitable for most everyday driving situations.

- However, it can be more complex and costly to manufacture and maintain compared to beam axles.

While beam axles are known for their strength and simplicity, independent suspension systems are favored for their superior ride comfort, handling, and adaptability to various road conditions. The choice between the two depends on the vehicle’s intended use, design goals, and the trade-off between load-carrying capacity and ride quality.

editor by CX 2023-11-09

China 4882518 Front Right CV Axle Shaft For Dodge Intrepid & Chrysler Concorde 4882520 electric rear axle kit

Yr: 1997-2, 4882520

Automobile Fitment: Chrysler

Reference NO.: PCV9535

Measurement: OEM STHangZhouRD

Substance: Metal

Design Amount: 4882518

Guarantee: 12 Months

Automobile Make: For American Vehicles

Part Variety: Driveshaft / Prop Shaft

Place: Entrance

Item Problem: New

Lifecycle Standing: Offered to Purchase

Fitment Type: Direct Substitution

Exterior: Machined

Packaging Specifics: Netural packing

Port: HangZhou ,ZheJiang ,HangZhou ,HangZhou

Recommend Products Products Description Product Information:Proprietary engineering procedures make sure that all CV Travel Axles satisfy OE type, in shape and perform.Neoprene boots are made with additional bellows, when needed, to resist bellow stress and cracking, which is the top result in of boot failure.An axle retaining nut is supplied with every unit for a hassle-cost-free set up, owing to the chance that the first retaining nut is worn or stripped.CV Travel Axle measurements are validated after assembly to guarantee a appropriate suit High high quality LM1274911 LM1274910 tapered roller bearing LM12749LM12711 LM12749 LM12711 Threads are precision rolled to ensure proper fit when axle nut is installed.Boot clamps are pneumatically crimped, creating a best seal between the boot and housing. Fitment: Fit for 1998 Chrysler Intrepid ES 3.2L V6 197cid/3200cc Suit for 1998 Dodge Intrepid SXT 3.2L V6 197cid/3200cc Suit for 1998-1999 Chrysler Intrepid Foundation 2.7L V6 167cid/2736cc, 3.2L V6 197cid/3200cc Fit for 1998-2000 Dodge Intrepid Base 2.7L V6 167cid/2736cc Match for 1998-2000 Dodge Intrepid ES 3.2L V6 197cid/3200cc Fit for 1998-2000 Dodge Intrepid ES Lujo 3.2L V6 197cid/3200cc Match for 1998-2001 Chrysler Concorde LXi 3.2L V6 197cid/3200cc Fit for 1998-2004 Chrysler Concorde LX 2.7L V6 167cid/2736cc In shape for 1999-2001 Chrysler Intrepid ES 2.7L V6 167cid/2736cc, 3.2L V6 197cid/3200cc Match for 1999-2001 Chrysler LHS Base 3.5L V6 215cid/3497cc In shape for 1999-2001 Dodge Intrepid ES 2.7L V6 167cid/2736cc, 3.2L V6 197cid/3200cc Suit for 1999-2004 Chrysler 300M Base 3.5L V6 215cid/3497cc Fit for 2000 Chrysler Intrepid Foundation 3.5L V6 215cid/3497cc, 2.7L V6 167cid/2736cc, 3.2L V6 197cid/3200cc Fit for 2000-2002 Dodge Intrepid R/T 3.5L V6 215cid/3497cc Match for 2001 Chrysler Concorde LX 3.2L V6 197cid/3200cc In shape for 2001-2003 Dodge Intrepid SE 3.5L V6 215cid/3497cc, 2.7L V6 167cid/2736cc Suit for 2001-2004 Chrysler Intrepid SE 3.5L V6 215cid/3497cc, 2.7L V6 167cid/2736cc Match for 2002 Chrysler Concorde LX 3.5L V6 215cid/3497cc Match for 2002, 2004 Chrysler Intrepid ES 3.5L V6 215cid/3497cc Match for 2002-2004 Chrysler Concorde LXi 3.5L V6 215cid/3497cc Fit for 2002-2004 Chrysler Concorde Restricted 3.5L V6 215cid/3497cc Suit for 2002-2004 Dodge Intrepid ES 3.5L V6 215cid/3497cc Suit for 2003 Chrysler Intrepid ES 3.5L V6 215cid/3497cc, 2.7L V6 167cid/2736cc In shape for 2003-2004 Dodge Intrepid SXT 3.5L V6 215cid/3497cc Match for 2004 Dodge Intrepid Law enforcement 3.5L V6 215cid/3497cc Suit for 2004 Dodge Intrepid SE 2.7L V6 167cid/2736cc Organization Details FAQ Q1. What is your conditions of packing?A: Usually, 23 bars slot kind commutator OD41.5ID35.3H14 motor armature commutator we pack our goods in plastic baggage and brown cartons. Certain according to your necessity.Q2. What is your terms of payment?A: T/T 30% as deposit, and 70% ahead of delivery. We will show you the photographs of the merchandise and packages just before you shell out the equilibrium.Q3. What is your terms of shipping and delivery?A: Usually is FOB, Certain according to your need.This fall. How about your delivery time? A: Usually, it will take thirty to 60 days after receiving your advance payment. The certain supply time is dependent on the products and the quantity of your purchase.Q5. CAN YOU Generate According TO THE SAMPLES?A: Yes, we can make by your samples or complex drawings. We can develop the molds and fixtures.Q6. WHAT IS YOUR SAMPLE Plan?A: We can source the sample if we have prepared parts in inventory, but the customers have to pay the sample value and the courier expense. When you location the official order, these fees can be deductible from the payment for items.Q7. DO YOU Examination ALL YOUR Goods Prior to Shipping? A: Of course, we have a hundred% take a look at before deliveryQ8: HOW DO YOU MAKE OUR Organization Extended-Expression AND Excellent Romantic relationship?A:1. We hold great high quality and aggressive price to make sure ourcustomers benefit2. We regard each and every customer as our buddy and we sincerely do business and make buddies with them, no subject where they come from.

How to Repair an Axle

An axle is the central shaft of a gear or wheel. The axle can be fixed to the wheels or the vehicle itself and rotates along with them. The axle may include bearings. This article discusses the different types and their functions. It also covers how to repair an axle. In addition to its function, an axle may include mounting points and bearings.

Structure

An axle is a part of railway machinery that helps move trains. It is made up of a cylinder and a system of springs. The axle is positioned near the center of the train’s wheels and is connected to the frame and wagon. Axle box bogies are used in economic trains.

Axles can be integral or detached, depending on the type of vehicle. An integral axle is the central part of the suspension system and supports the weight of the vehicle. A disengaged axle has two wheels on opposite sides. In a vehicle with independent suspension, the axles are matched together with independent suspension. Different types of axles are designed for different purposes, so it’s important to understand which type of axle is used for the vehicle you’re driving.

A conventional axle assembly consists of the hub assembly 10, brake disk 20, wheel bearing assembly 30, and knuckle 40. It also has a hub bolt 14. The wheel bearing assembly 30 is made up of the bearing 32, outer ring 36, and bearing connecting bolt 38. The wheel bearing assembly is connected to the hub using a hub.

The type of axle used in a vehicle is determined by the type of driving force that the axle is expected to deliver. Some vehicles use standard axles while others have custom-made axles to meet their specifications. This allows for better control over the wheels’ speed and torque. These differences can greatly affect the performance of your vehicle.

Full-floating axles are most common in light, medium, and heavy-duty trucks. These axles can handle more weight than their semi-floating counterparts. They also prevent the wheel from coming off in case of axle failure. Full-floating axles are used in some Land-Rover vehicles and are used in American stock car racing. In addition, full-floating axles help maintain wheel alignment and handle side thrust and driving torque.

The structure of an axle assembly comprises an input shaft, a brake disk, and the hub. The input shaft is connected to the drive pulley.

Function

Axle springs are used to support the axle. The spring rate depends on the amount of load applied to the axle. The position of the axle can be determined by detecting signals produced by a position sensor. The sensor detects a change in distance between the axle body and the chassis. The spring rate is then adjusted to provide the required level of deflection.

The differential between the spring supported and unsprung axle suspension can lead to dangerous operating conditions. An operator may not always be aware of the occurrence of a switch from spring-supported to unsprung condition, and may overtax the vehicle as a result. Thus, the proper operation of axles depends on a thorough understanding of axle functions.

The Michigan DOT study used mechanistic models and laboratory studies to develop axle factors. These factors describe the relative damage caused by a single distress to a standard axle. They were used to adjust the AASHTO-based LEFs for single axle weights and to derive new LEFs independent of ESALs.

Models for estimating service lives are based on the work of Timm et al. for the FHWA. These models assume accurate axle loading spectra and a small number of tightly defined scenarios. This greatly simplifies the task of estimating LEFs and improves the accuracy of results.

The MEPDG version of the model supports the NAPCOM and PaveDAT models. They show a considerable variation in the effects of different axle weights on various metrics of pavement condition. This is because different axle weights can cause different results in different sections, if they are associated with two failure mechanisms.

Types

There are many different types of axles, each with their own characteristics. The most common of these is the Ford 9-inch axle, which is found in most Blue Oval muscle cars and trucks. It is so popular that aftermarket companies even make versions for Chevy applications. This particular type of axle features a 3/8-inch square-drive fill plug and is reinforced with a Daytona-style pinion cartridge, which accommodates a stronger pinion head bearing and thicker inner ribbing.

Another type of axle is the rigid front axle, which uses leaf springs to provide suspension. These springs are fixed to spring seats on the axle beam. The axle beam and track rod are connected to each other using screws. The length and thickness of the axle tubes are important for the strength and performance of the axle.

The rear axle is responsible for transferring power to the driving wheels. The front axle, on the other hand, is responsible for processing road shocks and steering. The driving torque produces thrust in the wheels. This force must be transmitted to the chassis frame and body to move the vehicle. These are the most affordable types of axles, but they can also lead to problems.

While many axles are manufactured in standard formats, many of them are custom-made for a particular car, allowing for a more individualized look and performance. In addition to being custom-made for the vehicle, axle housing cases can be either a single unit or split like a banjo. The front opening of the axle housing is closed by a differential carrier, while the rear opening is covered by a spherical cover plate.

Different types of axles have different strengths and weaknesses. Typically, the weight of an axle should be proportionate to the vehicle’s weight and the pressure it will exert on the road. When the axle weight is higher, a vehicle will not be as efficient, as it will use more fuel to move at the same speed. This can cut into profit margins.

Different types of axles can have various purposes, but one main function is to transfer power from the engine to the wheels. These axles need to be durable and able to withstand the weight of a vehicle, as well as withstand accelerated forces.

Repair

If you notice any signs of wear or damage to the axle on your vehicle, you may need to repair it. This type of repair will not only protect the wheels, but will also increase the overall performance of your car. A good repair job can help you enjoy smoother driving and better control of your tires. However, there are certain precautions you must take before starting the repair.

To fix an axle, a mechanic must first determine the cause of the problem. This can involve replacing worn or broken parts, replacing them with new ones, and adjusting the car’s alignment. The mechanic will then tighten the fasteners and tires according to manufacturer specifications. Finally, the car will be road tested to ensure that everything is working properly.

A CV joint is also a common item to be replaced. The lubrication in these joints can become dirty, which causes them to wear out. A failing joint will make a clicking sound when it turns sharply. A failed joint may also affect the differential. This part of the car’s drivetrain contains a set of gears that transfer the rotational power of the engine to the wheels. Over time, the gears can wear out, resulting in high labour and replacement costs.

If your car has bent axles, it is important to repair them as soon as possible. Even if the damage is slight, the problem can lead to additional damage to your car’s wheels, CV joints, or other powertrain components. Thankfully, some insurance policies cover the cost of axle repair after an accident.

The average cost to repair an axle varies from about $450 to $900 before taxes. The cost depends on the size of the vehicle and the type of labor required. A rear axle repair can cost up to $700. In addition to labor fees, parts can cost as little as $50 to 70. The cost of the repair can also vary depending on the type of vehicle and the parts used.

If you notice bad vibrations in your vehicle, it’s likely that the axle has been damaged. These vibrations can cause problems with the handling of your vehicle and your comfort while driving.

editor by czh 2023-03-01

China Gjf High Quality Car Auto Drive Shaft Front CV Axle for Buick La Cross 2.0t 2016- C-GM140-8h axle bolt

Item Description

Item Description

one.We are manufacturer of cv push shaft,cv axle, cv joint and cv boot, we have far more than 20-several years knowledge in creating and selling car parts.

two.We have rigorous top quality handle, the good quality of our goods is very excellent.

three.We are skilled in distinct industry about the planet.

4.The critiques our buyers presented us are quite good, we have self-assurance in our goods.

5.OEM/ODM is obtainable, satisfy your specifications effectively.

6.Big warehouse, enormous stocks!!! welcoming for those clients who want some amount.

seven.Ship products out very fastly, we have stock.

| Product Name | Drive shaft | Material | 42CrMo alloy steel |

| Car fitment |

Chevrolet |

Warranty | twelve months |

| Model | Ranger 3. TDI/MAZDA Fighter AT/MT | Place of origin | ZHangZhoug, China |

| year | 2007-2011 | MOQ | four PCS |

| OE number | C-GM140-8H | Shipping and delivery time | 1-7 days |

| OEM/ODM | Sure | Brand | GJF |

| Packing size | seventy two*23.5*23.5 | Payment | L/C,T/T,western Union,Money,PayPal |

| Sample service | Is dependent on the circumstance of stock | Weight | eight.2088KG |

Thorough Photos

Client Overview

Packaging & Shipping

FAQ

|

US $32 / Piece | |

4 Pieces (Min. Order) |

###

| After-sales Service: | 12 Months |

|---|---|

| Condition: | New |

| Axle Number: | 1 |

| Application: | Car |

| Certification: | ASTM, CE, DIN, ISO |

| Material: | Alloy |

###

| Samples: |

US$ 32/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Product Name | Drive shaft | Material | 42CrMo alloy steel |

| Car fitment |

Chevrolet |

Warranty | 12 months |

| Model | Ranger 3.0 TDI/MAZDA Fighter AT/MT | Place of origin | Zhejiang, China |

| year | 2007-2011 | MOQ | 4 PCS |

| OE number | C-GM140-8H | Delivery time | 1-7 days |

| OEM/ODM | Yes | Brand | GJF |

| Packing size | 72*23.5*23.5 | Payment | L/C,T/T,western Union,Cash,PayPal |

| Sample service | Depends on the situation of stock | Weight | 8.2088KG |

|

US $32 / Piece | |

4 Pieces (Min. Order) |

###

| After-sales Service: | 12 Months |

|---|---|

| Condition: | New |

| Axle Number: | 1 |

| Application: | Car |

| Certification: | ASTM, CE, DIN, ISO |

| Material: | Alloy |

###

| Samples: |

US$ 32/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Product Name | Drive shaft | Material | 42CrMo alloy steel |

| Car fitment |

Chevrolet |

Warranty | 12 months |

| Model | Ranger 3.0 TDI/MAZDA Fighter AT/MT | Place of origin | Zhejiang, China |

| year | 2007-2011 | MOQ | 4 PCS |

| OE number | C-GM140-8H | Delivery time | 1-7 days |

| OEM/ODM | Yes | Brand | GJF |

| Packing size | 72*23.5*23.5 | Payment | L/C,T/T,western Union,Cash,PayPal |

| Sample service | Depends on the situation of stock | Weight | 8.2088KG |

Axle Types

An axle is the central shaft of a rotating gear or wheel. Axles are either fixed to the wheels or mounted directly to the vehicle. They rotate with the wheels and can be equipped with bearings for smooth operation. Axle types include Czpt axles, Drop out axles, and Splines. Each has a unique design and function.

Spindles

The spindles on a vehicle’s axle are the main components that connect the wheels to the axle. They mount the wheels on the axle and fasten the braking system to the axle assembly. The spindles are fastened to the axle assembly with king pins and ball joints. They also fasten the wheel hub to the spindle via a castelated nut. In both applications, axle spindles are pivot points that are used to make turning motion possible.

There are three types of spindles for an axle. Typically, the spindles are bolted to the ends of a tubular axle, which is suspended by springs. The third type is a short stub axle, which uses a torsion beam to help the axle maintain a smooth ride over bumpy terrain.

Czpt axles

Czpt axles are available in a variety of configurations. From beam-to-independent designs to single-point-to-double-point designs, there’s a Czpt axle to fit your needs. These axles are designed to provide maximum power in a small package. Czpt has a proven track record of innovation and durability.

Czpt axles are found in front-end steering vehicles and heavy-duty pickups. Some models only use the front axle. There are also Czpt axles for light-duty pickups. You can easily recognize a Czpt axle by its shape. Some online sources offer diagrams to help you identify the axle.

Among the most popular Czpt axles are the Czpt 60 and the Czpt 44. Both models are desirable in their own right. You can order Czpt axle parts from the Czpt website. These products include u joints, differential cases, and loc pins. These parts can be purchased online, and they will be delivered right to your door.

In addition to the Czpt 60 front axle, Czpt axles also feature great aftermarket support. They can be upgraded with locking differentials, limited slip differentials, and high-capacity differential covers. They also feature heat-sinks that keep the axle cool. Czpt axles are also compatible with nearly every traction aid in the market.

Czpt is a global leader in driveline products and genuine service parts. With over a century of experience manufacturing quality products, Czpt axles provide performance and reliability.

Drop out axles

Drop out axles are crucial for mounting a front wheel to a bike. If the axles are not present, the wheel will not be able to be mounted. These dropouts are made of either steel or aluminum. They are 5.8mm thick. Axles with quick release axle hubs are compatible with steel dropouts.

Axle manufacturers make different dropout axles that are compatible with different axle sizes. These axles are available in a wide range of styles. The Shimano modular dropout, for example, is available in three main axle specifications: Road, Track, and Maxle. These dropouts are also available with different axle pinions.

Drop out axles can be quick release or through. Quick release axles are lighter than thru axles. They weigh approximately 60 to 80 grams. The difference between quick release and thru axles is in the thread pitch. Quick release axles have a smaller pitch than thru axles, which allows for easier installation and removal.

Thru axles are a popular choice for mountain bikes. They prevent the front wheel from coming out while riding. They are more secure and can prevent a wheel from coming off when moving. They are usually made of a thicker rod and screw into the frame. Both types of dropouts have their advantages and disadvantages. You should choose the type that works best for your needs. This is a decision that you will have to make on your own.

CV joints

When your vehicle is in motion, the CV joints on your axle transfer torque to the wheels. Although these joints come in a wide variety of designs, they all contain a bearing assembly that allows them to move. These joints are protected by a rubber boot that is filled with grease to keep them lubricated. When they become worn, they can cause your car to shudder and vibrate while accelerating.

To avoid joint failure, it is important to keep the CV joints free of road debris. Luckily, the boots are made of durable rubber, and a good quality one can last 100,000 miles. Unfortunately, if the rubber boot is torn, dirt and moisture can leak into the joint. Therefore, it’s important to inspect the boots regularly, and replace them if necessary.

Damaged CV joints can make control of your vehicle extremely difficult. They can also cause your steering wheel to jerk when you’re accelerating, increasing the risk of an accident. A damaged CV joint can also lead to axle separation, which can cause massive damage and a serious safety risk. However, if you don’t have the funds to replace the joint, you can repair the problem by applying a sleeve.

Unlike other drive systems, CV axles can transfer torque at an angle. This is possible because of the constant velocity joints. They’re akin to the univeersal joints on tail shafts, except they work on a much larger angle. This allows the drive shaft to transfer torque to the front wheels smoothly. It also allows the axle to move up and down.

A damaged CV axle will make a characteristic clicking sound when you’re turning the vehicle. This noise is very distinctive and can only be heard when the vehicle is in motion. If you hear this noise, then the joint is worn and is in danger of failure. If this noise is loud and consistent, you’ll need to replace it.

editor by czh 2022-12-19

China OEM Kawacvjoints OEM 2200300U0040 Front Drive Shaft CV Joint Axle for JAC S7 1.5T MT L near me supplier

Design: REFINE S7, SEI7, T80

Calendar year: 2019-

OE NO.: 2200300U0040

Car Fitment: JAC

Reference NO.: twelve-216001

Measurement: 12*12*seventy five

Substance: Steel

Product Number: 2200300U0040

Guarantee: 31069 HangZhous

Car Make: JAC S7 1.5T MT L

OE: 2200300U0040

Item Title: CV Joint Axle

MOQ: 10 Pcs

Certificate: ISO9001

Packing: Neutral Packing

Cost: Make contact with us

Situation: Front Remaining Right

Manufacturer: Kawacvjoints

Edge: 20 A long time Expertise

Delivery time: 7-thirty Times

Packaging Specifics: PACKING: PACKING BOX IS Very same AS CLIENT’S BOX , Each and every CV JOINT BE PACKED IN A single BOX WITH Restore KITS, THEN 4 Boxes IN 1 CARTON

Please get in touch with us to verify your types Items Description Automotive Chassis Parts Transmission Push Shaft C.V. Axle NameDRIVESHAFTOE No.2200300U0040Car Model:JAC S7 1.5T MT LWarranty50000 kmMOQ10PCS Specifications1. We have whole variety for a number of frequent model travel shaft.2. In excess of 20 several years of producing auto parts.3. 50000 km top quality assure.4. a hundred% Inspection just before shipment. Packing & 3Y 4Y GEARBOX FOR CZPT HIACE HILUX Shipping and delivery Packing Specifics : Box+carton+palletDelivery Particulars : 5-30 days right after get completed.Typically it is 5-7 times if the items are in stock. Or it is fifteen-twenty times if the items are not, it is according to thequantity. Firm Profile About us.We have been specializing in the manufacturing of automotive components and accessories since 2003. We created our manufacturer “Kawacvjoints”, aiming to create it to 1 of the most famous vehicle areas maker. We have our own manufacturing facility and all our items are created under rigid regulation.We guarantee to offer our consumers with higher top quality and outstanding merchandise of all time. Our Manufacturing unit Suggest Products FAQ Q1. What is your conditions of packing?A: Usually, CW12 CW18 CT18 CT26 CT35 CT45 CT50 Final Swing Drive CW CT CR Observe Drive Hydraulic Reducer Oerlikon CZPT Planetary Gearbox we pack our items in neutral brown containers and brown cartons. If you have legally registered patent, we can pack the merchandise in your branded packing containers right after getting your authorization letters.Q2. What is your phrases of payment?A: T/T thirty% as deposit, and 70% before delivery. We will display you the photographs of the goods and packages just before you shell out the harmony.Q3. What is your phrases of supply?A: EXW, FOB, 551B0-JF00C Vehicle Components Manage Arm Knuckle Bushing For NISSAN CEDRIC CIMA GLORIA CFR, CIF, DDU.Q4. How about your shipping time?A: Typically, it will just take 30 to sixty times after obtaining your progress payment. The particular shipping and delivery time relies upon on the things and the quantity of your buy.Q5. Can you produce according to the samples?A: Yes, we can create by your samples or complex drawings. We can create the molds and fixtures.Q6. What is your sample coverage?A: We can provide the sample if we have all set elements in inventory, K collection gearbox helical bevel equipment models hollow shaft speed reducer gear box but the consumers have to pay out the sample cost and the courier expense.Q7. Do you examination all your goods prior to shipping?A: Sure, we have a hundred% check prior to deliveryQ8: How do you make our company lengthy-expression and excellent connection?A:1. We maintain good quality and competitive price to guarantee our consumers advantage 2. We respect every buyer as our pal and we sincerely do enterprise and make friends with them, no issue exactly where they occur from.

Why Checking the Generate Shaft is Essential

If you hear clicking noises whilst driving, your driveshaft may need to have mend. An knowledgeable mechanic can notify if the sound is coming from one particular facet or the two sides. This difficulty is usually associated to the torque converter. Read through on to learn why it really is so important to have your driveshaft inspected by an auto mechanic. Below are some signs and symptoms to seem for. Clicking noises can be induced by a lot of different things. You need to very first verify if the noise is coming from the entrance or the rear of the car.

hollow generate shaft

Hollow driveshafts have several positive aspects. They are light and lessen the total weight of the automobile. The premier producer of these components in the entire world is CZPT. They also supply lightweight options for different applications, this sort of as higher-overall performance axles. CZPT driveshafts are created making use of condition-of-the-art engineering. They supply outstanding top quality at aggressive charges.

The inner diameter of the hollow shaft reduces the magnitude of the inside forces, therefore decreasing the volume of torque transmitted. As opposed to solid shafts, hollow shafts are acquiring more robust. The materials inside the hollow shaft is marginally lighter, which even more reduces its weight and total torque. Even so, this also raises its drag at higher speeds. This indicates that in numerous apps hollow driveshafts are not as efficient as reliable driveshafts.

A standard hollow travel shaft is composed of a very first rod fourteen and a next rod fourteen on equally sides. The 1st rod is connected with the next rod, and the second rod extends in the rotation path. The two rods are then friction welded to the central area of the hollow shaft. The frictional warmth generated in the course of the relative rotation assists to connect the two areas. Hollow generate shafts can be utilized in interior combustion engines and environmentally-friendly autos.

The primary benefit of a hollow driveshaft is excess weight reduction. The splines of the hollow generate shaft can be created to be more compact than the outside the house diameter of the hollow shaft, which can substantially lessen weight. Hollow shafts are also less most likely to jam in comparison to solid shafts. Hollow driveshafts are anticipated to ultimately occupy the entire world industry for automotive driveshafts. Its rewards contain fuel efficiency and higher versatility compared to strong prop shafts.

Cardan shaft

Cardan shafts are a common decision in industrial machinery. They are used to transmit electricity from one particular machine to yet another and are offered in a range of sizes and styles. They are available in a variety of components, which includes metal, copper, and aluminum. If you plan to set up one particular of these shafts, it is critical to know the various kinds of Cardan shafts offered. To locate the greatest choice, look through the catalog.

Telescopic or “Cardan” prop shafts, also recognized as U-joints, are perfect for productive torque transfer between the drive and output program. They are productive, lightweight, and strength-successful. They make use of sophisticated approaches, such as finite element modeling (FEM), to ensure maximum functionality, fat, and performance. Moreover, the Cardan shaft has an adjustable length for effortless repositioning.

One more well-liked option for driveshafts is the Cardan shaft, also acknowledged as a driveshaft. The goal of the driveshaft is to transfer torque from the engine to the wheels. They are typically employed in large-functionality car engines. Some kinds are manufactured of brass, iron, or steel and have special area types. Cardan shafts are offered in inclined and parallel configurations.

One Cardan shafts are a frequent replacement for normal Cardan shafts, but if you are seeking for twin Cardan shafts for your motor vehicle, you will want to select the 1310 sequence. This type is wonderful for lifted jeeps and demands a CV-appropriate transfer case. Some even demand axle spacers. The dual Cardan shafts are also created for lifts, which indicates it really is a very good decision for boosting and decreasing jeeps.

universal joint

Cardan joints are a great choice for generate shafts when operating at a continuous velocity. Their style enables a continuous angular velocity ratio among the enter and output shafts. Dependent on the application, the suggested velocity limit might fluctuate dependent on the functioning angle, transmission power, and software. These tips need to be primarily based on strain. The highest permissible speed of the push shaft is identified by identifying the angular acceleration.

Because gimbal joints don’t call for grease, they can final a prolonged time but eventually fail. If they are poorly lubricated or dry, they can lead to steel-to-steel make contact with. The identical is accurate for U-joints that do not have oil filling functionality. Although they have a prolonged lifespan, it can be difficult to location warning symptoms that could point out impending joint failure. To avoid this, verify the push shaft frequently.

U-joints should not exceed seventy per cent of their lateral vital velocity. However, if this pace is exceeded, the part will expertise unacceptable vibration, decreasing its beneficial lifestyle. To decide the greatest U-joint for your application, remember to make contact with your common joint provider. Typically, reduced speeds do not demand balancing. In these instances, you ought to take into account utilizing a bigger pitch diameter to lessen axial drive.

To minimize the angular velocity and torque of the output shaft, the two joints have to be in phase. Therefore, the output shaft angular displacement does not totally stick to the enter shaft. As an alternative, it will lead or lag. Determine 3 illustrates the angular velocity variation and peak displacement lead of the gimbal. The ratios are demonstrated under. The correct torque for this application is 1360 in-Ibs.

Refurbished travel shaft

Refurbished driveshafts are a good choice for a quantity of reasons. They are less expensive than brand new choices and usually just as reliable. Driveshafts are vital to the operate of any auto, truck, or bus. These parts are made of hollow metal tubes. While this assists reduce weight and expense, it is vulnerable to exterior influences. If this occurs, it may crack or bend. If the shaft suffers this sort of hurt, it can trigger significant harm to the transmission.

A car’s driveshaft is a vital component that transmits torque from the motor to the wheels. A1 Generate Shaft is a global supplier of automotive driveshafts and connected elements. Their manufacturing facility has the functionality to refurbish and mend practically any make or design of driveshafts. Refurbished driveshafts are offered for each make and design of vehicle. They can be found on the market for a assortment of autos, such as passenger vehicles, vehicles, vans, and SUVs.

Strange noises show that your driveshaft demands to be replaced. Worn U-joints and bushings can cause too much vibration. These elements lead to put on on other parts of the drivetrain. If you recognize any of these signs, you should take your vehicle to the AAMCO Bay Spot Middle for a complete inspection. If you suspect hurt to the driveshaft, will not wait yet another minute – it can be very unsafe.

The expense of changing the drive shaft

The expense of replacing a driveshaft may differ, but on typical, this fix expenses among $two hundred and $1,500. Whilst this cost may possibly differ by vehicle, the value of elements and labor is normally equivalent. If you do the mend yourself, you ought to know how significantly the components and labor will expense prior to you start off work. Some components can be a lot more costly than other individuals, so it’s a great idea to examine the cost of a number of locations ahead of selecting where to go.

If you discover any of these signs and symptoms, you need to seek out a restore shop right away. If you are even now not confident if the driveshaft is ruined, do not generate the auto any length until it is repaired. Signs and symptoms to look for contain deficiency of electricity, problems shifting the car, squeaking, clanking, or vibrating when the automobile is moving.

Parts utilised in push shafts contain heart help bearings, slip joints, and U-joints. The price tag of the driveshaft may differ by car and could range by model of the exact same yr. Also, various kinds of driveshafts demand various mend techniques and are significantly far more pricey. General, even though, a driveshaft substitution fees in between $three hundred and $1,three hundred. The process may take about an hour, based on the vehicle model.

A number of factors can guide to the require to exchange the drive shaft, like bearing corrosion, broken seals, or other parts. In some situations, the U-joint signifies that the drive shaft wants to be changed. Even if the bearings and u-joints are in excellent situation, they will eventually crack and call for the substitute of the drive shaft. Nevertheless, these areas are not inexpensive, and if a destroyed driveshaft is a symptom of a even bigger issue, you must consider the time to substitute the shaft.

China wholesaler CCL Front Drive Axle Shaft FOR CZPT 43410-0W18043410-0656043410-0669043410-0664043410-0686043410-4403043410-0W160 wholesaler

Model: HIGHLANDER / KLUGER (_U2_)

Calendar year: 2000-2007

OE NO.: 43410-06650, 43410-06B00, China Supply OEM Mechanical Transmission Elements QD Bushing Metal American Tapered And QD Bushing 43410-0W180, 43410-06690, High Precision Planetary Gearbox Gearbox For Servo Motor Planetary Equipment Reducer VRSF-5C-K-400-GCII Planetary Equipment Reducer 43410-06640

Vehicle Fitment: Toyota

Reference NO.: TO-60A48, a hundred and fifty 1668-SX

Dimensions: 980MM

Substance: Steel

Design Number: TO-8-122

Warranty: 12 Months

Auto Make: for ES350/ACV40/RX400-RL154/ES240/GSV40

Item Title: Entrance Generate Shaft

OEM: 43410-06650

Vehicle Design: for ES350/ACV40/RX400-RL154/ES240/GSV40

Payment: TT.paypal.Western Union.Trade Assurance

MOQ: 4pcs

Brand: CCL

Delivery: Sea DHL FEDEX EMS TNT

Sample: Avialable

High quality: Higher-Quality

Packing: CCL packaging

Packaging Specifics: 1. CCL, nmrv worm equipment box transmission gearbox agricultural nmrv075 gearbox 10 to 1ratio gearbox PIN or EQC manufacturer bundle. 2. The buyer manufacturer deal. 3. The neutral bundle.

Port: HangZhou

Particulars Images Product name:Push SHAFT FOR ES350/ACV40/RX400-RL154/ES240/GSV40OEM Amount: 43410-06B00/43410-0W160/4341033330Measurement:980MMFat:12KGSFITTING Place:Front LManufacturer:CCLMaterials:55 steelMOQ:10pcs Guarantee:12 monthsample:surePackage:cclShipping time:in stock in 7days Merchandise Description Utilization description Business Profile Staff appearance Certifications Item packaging FAQ

Generate shaft sort

The driveshaft transfers torque from the engine to the wheels and is liable for the clean working of the motor vehicle. Its layout experienced to compensate for differences in length and angle. It must also make sure excellent synchronization among its joints. The generate shaft must be manufactured of higher-grade resources to accomplish the very best equilibrium of stiffness and elasticity. There are three primary types of push shafts. These consist of: conclude yokes, tube yokes and tapered shafts.

tube yoke

Tube yokes are shaft assemblies that use metallic components as the principal structural element. The yoke involves a uniform, considerably uniform wall thickness, a very first stop and an axially extending next end. The first diameter of the drive shaft is better than the second diameter, and the yoke further contains a pair of opposing lugs extending from the second conclude. These lugs have holes at the finishes for attaching the axle to the car.

By retrofitting the driveshaft tube conclude into a tube fork with seat. This valve seat transmits torque to the driveshaft tube. The fillet weld 28 enhances the torque transfer ability of the tube yoke. The yoke is generally manufactured of aluminum alloy or steel substance. It is also used to join the generate shaft to the yoke. Different patterns are feasible.

The QU40866 tube yoke is utilized with an external snap ring type universal joint. It has a cup diameter of 1-3/sixteen” and an general width of 4½”. U-bolt kits are yet another selection. It has threaded legs and locks to help protected the yoke to the generate shaft. Some functionality cars and off-highway cars use U-bolts. Yokes should be machined to acknowledge U-bolts, and U-bolt kits are frequently the preferred accessory.

The end yoke is the mechanical element that connects the generate shaft to the stub shaft. These yokes are typically created for particular drivetrain parts and can be personalized to your requirements. Pat’s drivetrain gives OEM substitute and customized flanged yokes.

If your tractor makes use of PTO factors, the cross and bearing kit is the best instrument to make the link. Moreover, cross and bearing kits support you match the correct yoke to the shaft. When choosing a yoke, be positive to measure the outside the house diameter of the U-joint cap and the inside of diameter of the yoke ears. Right after using the measurements, check with the cross and bearing identification drawings to make sure they match.

Although tube yokes are generally simple to change, the greatest final results appear from a qualified equipment store. Focused driveshaft specialists can assemble and balance finished driveshafts. If you are doubtful of a particular aspect, make sure you refer to the TM3000 Driveshaft and Cardan Joint Service Handbook for more data. You can also seek the advice of an excerpt from the TSB3510 manual for details on angle, vibration and runout.

The sliding fork is yet another essential part of the drive shaft. It can bend more than tough terrain, allowing the U-joint to hold spinning in more durable situations. If the slip yoke fails, you will not be capable to push and will clang. You want to change it as before long as attainable to stay away from any harmful driving circumstances. So if you notice any dings, be positive to verify the yoke.

If you detect any vibrations, the drivetrain might need to have adjustment. It’s a basic method. First, rotate the driveshaft until finally you locate the correct alignment between the tube yoke and the sliding yoke of the rear differential. If there is no apparent vibration, you can wait for a while to solve the dilemma. Hold in brain that it may possibly be practical to postpone repairs temporarily, but it could lead to greater problems later on.

stop yoke

If your driveshaft demands a new end yoke, CZPT has numerous drivetrain options. Our automotive finish yoke stock contains keyed and non-keyed alternatives. If you need tapered or straight holes, we can also make them for you.

A U-bolt is an industrial fastener that has U-formed threads on its legs. They are often utilized to join two heads again to again. These are hassle-free options to help preserve drivetrain parts in location when driving over tough terrain, and are usually suitable with a range of designs. U-bolts need a specially machined yoke to settle for them, so be positive to get the right size.

The sliding fork will help transfer electrical power from the transfer scenario to the driveshaft. They slide in and out of the transfer case, permitting the u-joint to rotate. Sliding yokes or “slips” can be purchased independently. Whether or not you want a new one or just a few elements to improve your driveshaft, 4 CZPT Areas will have the parts you want to restore your motor vehicle.

The end yoke is a required part of the travel shaft. It connects the generate practice and the mating flange. They are also utilized in auxiliary electrical power equipment. CZPT’s drivetrains are stocked with a range of flanged yokes for OEM programs and custom made builds. You can also find flanged yokes for continuous velocity joints in our in depth stock. If you don’t want to modify your current drivetrain, we can even make a personalized yoke for you.